Despite our most valiant efforts, sometimes ice accumulates on our aircraft. This might seem like a showstopper, at least until things thaw out, but options for getting rid of it do exist, depending on the airport and aircraft’s capability.

An ounce of prevention is worth a pound of cure, as the saying goes. We covered the prevention part in February’s article, Anti-Ice Systems, And How To Use Them. This month we’ll discuss the cure—what happens when the ice is already stuck to the plane.

Ground Icing

There are some signs that an aircraft left outside will be hampered by winter contamination. If there was any sort of freezing precipitation and unfavorable melting conditions, odds are you will arrive to an aircraft about as snowed in as your car. Thankfully, frost on your car is a great indicator of frosty wings. When I consider whether to hangar an aircraft at an overnight destination, I’ll check the temperature/dewpoint spread and wind. With freezing weather, high levels of moisture and calm winds, the chances are high frost will form. Which makes this a good time to mention the clean aircraft concept.

From Advisory Circular AC 135-16, Ground De-icing and Anti-Icing Training and Checking: “The current regulations in FAR Parts 121 and 135 rely on the ‘clean aircraft’ concept; i.e., that no person may takeoff an airplane when frost, ice, or snow is adhering to the wings, control surfaces, or propellers of the airplane.”

From AC 135-17, Small Aircraft De-Icing: “Adverse effects of ice, snow, or frost on aircraft performance and flight characteristics, including: decreased thrust, decreased lift, increased stall speed, trim changes, and altered stall characteristics and handling qualities.”

Even a small amount of frost on a lifting or control surface adds weight and lowers lifting capability. The normalization of deviance can creep in, and the number of times I have seen a pilot utter some form of “I’ve taken off with this much frost before and it was fine” is maddening. Adopting this attitude is dangerous and the antithesis of what we should strive for as aviators.

Removing Ground Icing

Of course, it’s best if the ice never gets on the airplane. If it does, roll the aircraft into a heated hangar, if possible. If temperatures are freezing outside, any melted ice will refreeze when it emerges. Take care that ice doesn’t form in the belly or inside control surfaces. Long story short, this method may involve wiping the aircraft down.

Even if it’s freezing outside, rolling the aircraft into the sun can work wonders. The upside is that it’s free and easy; the downside it is requires sunshine and relatively warm weather. Positioning the aircraft so the sun is evenly distributed across the aircraft is essential.

Mechanical means—wiping, brushing, sweeping—require real work and risk damaging antennas, sheet metal and paint. At our flight school, we had a machine we lovingly called “The Dragon.” It was a propane tank with a pilot flame and a hose, generating enough heat to melt frost off. The flight instructor would man the dragon, with their dutiful student, towel in hand, drying off the surface behind.

De-Icing Fluid

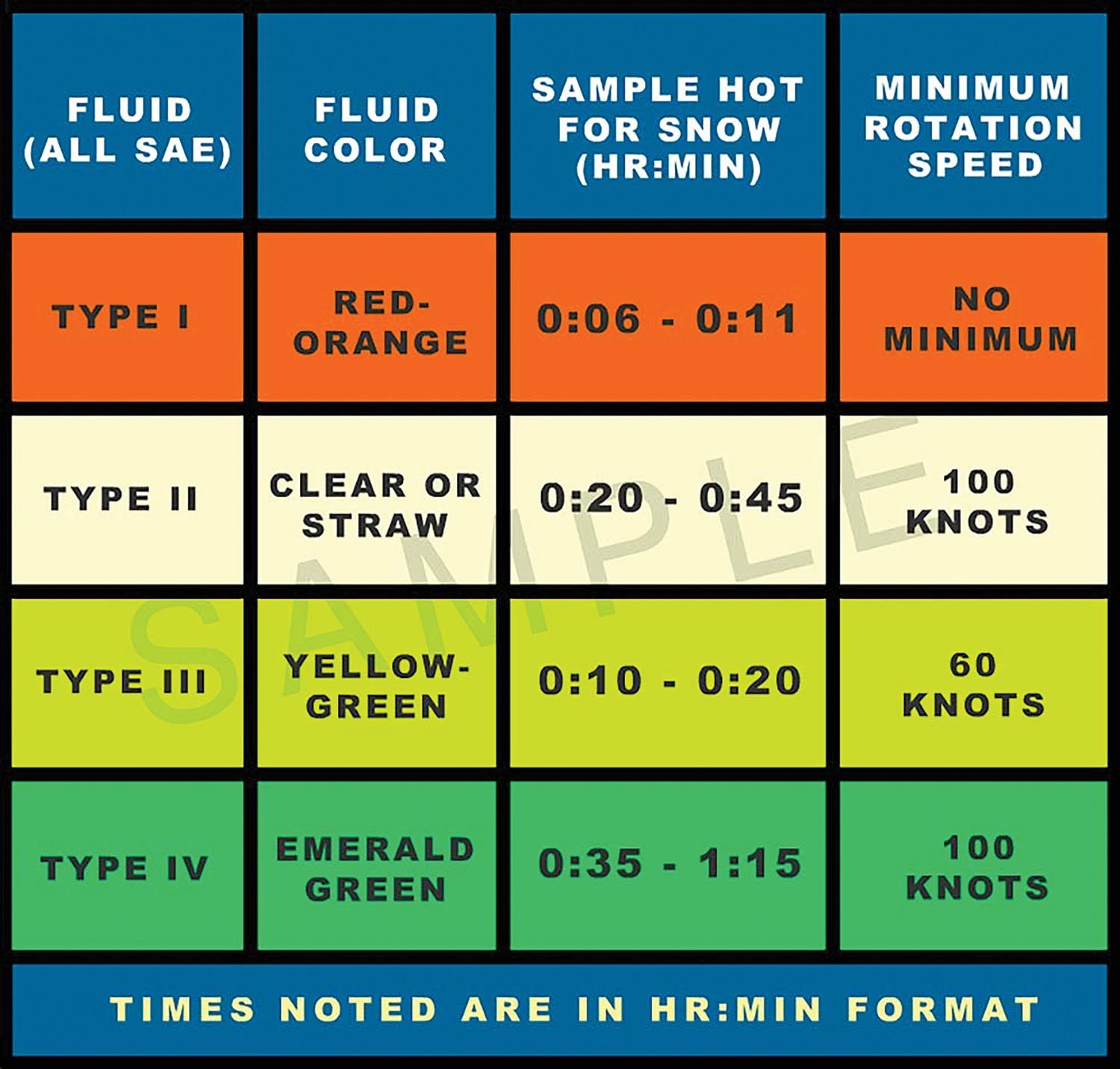

The purpose of de-ice/anti-ice fluids is to remove any existing buildup and prevent additional accretion, if required. An important factor to consider while using anti-icing fluids is holdover time (HOT), the estimated time that deicing/anti-icing fluid will prevent the formation of frost or ice and the accumulation of snow on the critical surfaces of an aircraft. Fluids are generally differentiated into types 1-4. The sidebar above has the details.

De-icing to remove existing ice or frost, where no falling frozen precipitation exists, is the simplest. Generally, you will speak with the de-icing crew outside the aircraft (hopefully in a warm FBO). If published, you can provide a diagram of the areas where fluid should be applied. Avoid spraying fluid into the following: engine inlets, engine exhaust, ram air inlets, brakes, windshields, cabin windows, pitot heads, static ports and AoA vanes.

Once the application of fluid is complete, it is important to confirm the lifting surfaces are completely clear of contaminates. If you are de-icing with the engine off, you can simply exit the aircraft and check. If you are hot de-icing, meaning with engines running, you will be relying on the trained de-icing professional. They should finish the job saying some form of the following: “The application of type 1 fluid began at 1200 and ended at 1210. The aircraft is free from contaminates.”

If there is still freezing precipitation, standard practice is to apply type 1 to remove existing contaminates followed by type 3 or 4 to prevent further accumulation. Using current holdover tables, provided each year by the FAA, you can make an educated guess based on the temperature, precipitation type and intensity, and the type of fluid used, how long it will take for the fluid to fail. A de-icing fluid fails when enough water dilutes the concentrate and prevents additional absorption of frozen precipitation. It can be difficult to tell if a fluid fails, especially if the wings are not visible from the cockpit. When in doubt, find an area on the airport to shut the aircraft down and check, or have trusted ground operation personnel check.

Lastly, de-icing fluid is not pleasant stuff to be around. Any sort of air conditioning in the aircraft should be shut off to avoid fumes entering the aircraft. Of course, if you have never done this or it has been a while, always review the manufacturer’s guidance.

NASA maintains an online aircraft icing training and reference resource through its Glenn Research Center: aircrafticing.grc.nasa.gov/. The available materials include the following description of de- and anti-icing fluids.

NASA maintains an online aircraft icing training and reference resource through its Glenn Research Center: aircrafticing.grc.nasa.gov/. The available materials include the following description of de- and anti-icing fluids.

Type 1: Generally considered de-icing fluid due to extremely short holdover times, this is the thinnest fluid available. The low viscosity is a double-edged sword. It shears off at slow speeds (60 knots), making it effective for small aircraft. On the downside, the fluid will not hold up against freezing precipitation for long and has the shortest holdover times, often under five minutes.

Types 2 and 4: Considered anti-icing fluids, Type 2 and 4 have thickening agents to ensure the fluid stays on the aircraft longer and absorbs more freezing precipitation. The results include longer holdover times, and a requirement of a minimum rotation speed of 100 knots. If the aircraft does not reach this speed prior to liftoff, the fluid can remain on the wing and cause weight and lift issues similar to ice and frost.

Type 3: Type three fluids are a newer hybrid of types 1 and 2/4, with thickening agents for longer holdover times but they are formulated to shear off at lower speeds. It’s a great compromise for aircraft that do not reach 100 knots on rotation but need some degree of holdover times.

In-Flight Icing

Once you have been de-iced on the ground, or if taking off into icing conditions that do not exist on the ground, the aircraft’s anti-icing systems will already be active. The difference is de-icing systems are not activated until ice accumulates. Typically, this is a wing-mounted inflatable boot system. Bleed air or air from pumps will be diverted to a rubber membrane on the leading edge of the wing/tail. This rapidly inflates the leading edge, fracturing the ice. The inflation/deflation cycle combined with air flowing over the wings should remove the worst of it. The pilot may need to activate the boots manually after a certain amount of buildup. Automatic systems work on a preset timed cycle. See the sidebar above.

Bleed-air systems divert hot air from a turbine engine to the leading edges of the wings and tail, melting any buildup and preventing further accumulation. When engine bleed air is used, climb performance is reduced and a minimum power setting may be required.

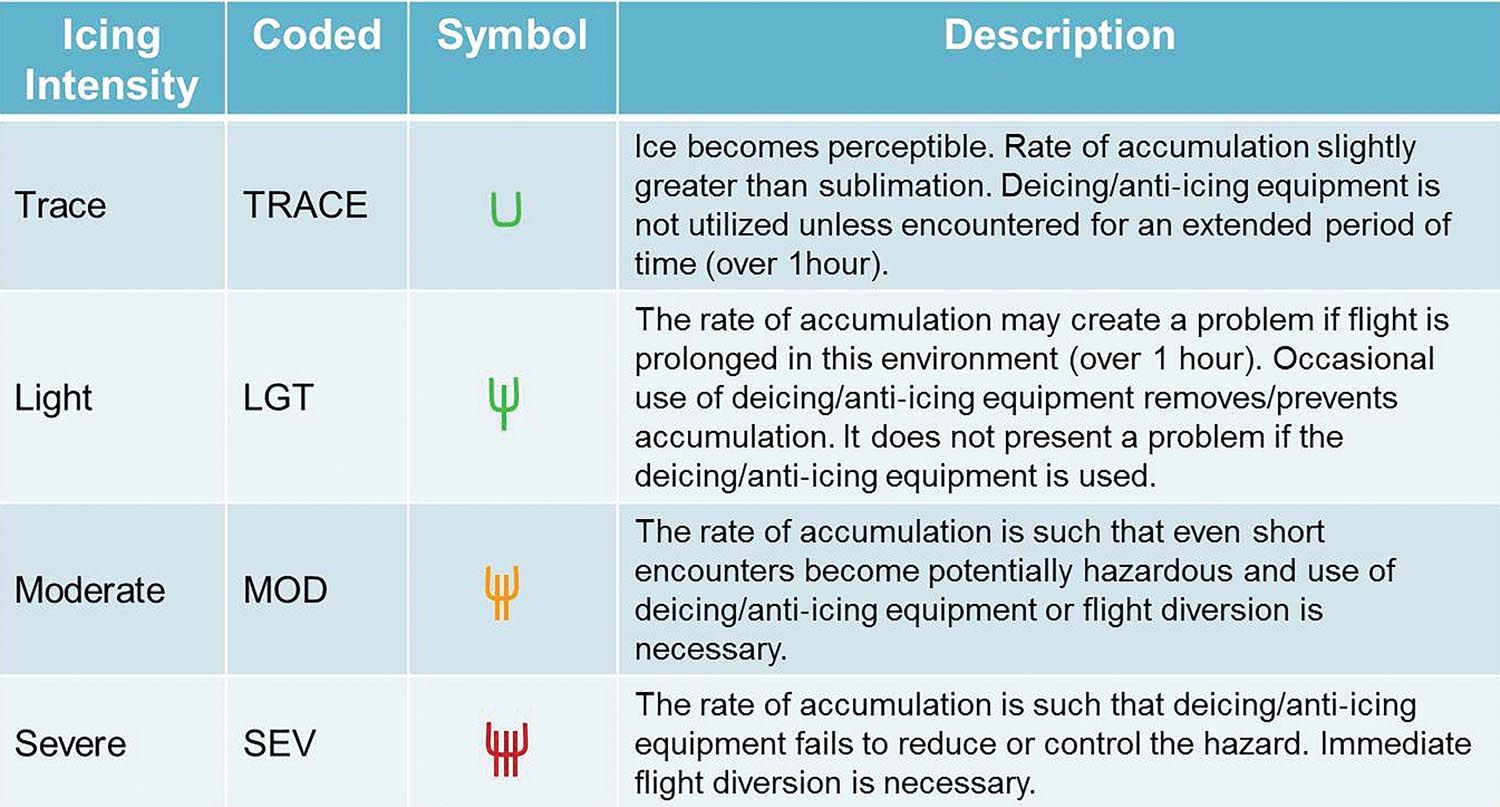

The way icing intensity is reported inherently depends on the capabilities of the aircraft’s de-ice and anti-ice system. Much like turbulence and other Pireps, consideration of the aircraft’s type is critical. Trace or light icing for an A320 may be moderate in a SR-22. While I do not recommend prolonged flight in icing conditions, accurate reporting to ATC is valuable and reviewing intensity charts like the one from NOAA above is always worth reviewing if it has been a minute.

Final Thoughts

Icing conditions create headaches for pilots every winter. Proper planning and high-quality ADM pave the way to a safe outcome. If ground deicing presents any undue risk, delaying or rescheduling the flight may be required.

In-flight icing is extremely dynamic, and if there is any indication of the aircraft’s systems being overwhelmed or failing, immediate action is needed to exit icing conditions, including landing at a nearby suitable airport.

If you have the equipment and resources, winter weather flying can be challenging and rewarding. Without the equipment and resources, it can be a short, miserable experience.

There’s been something of a debate on how and when deicing boots should be activated. One camp advocates waiting until some ice has accumulated before inflating the boots. For example, the documentation for a Cessna 402 says of the boots: “ACTUATE when ice accumulates between ¼ to ½ inch. Repeat as necessary, allowing at least 45 seconds between actuations.”

Newer guidance from the FAA and NTSB tells us that’s a bad idea. Here’s FAA Advisory Circular 91-74B: “A traditional concern in the operation of pneumatic boots has been ice bridging…. As the deformed ice hardens and accretes additional ice, the boot may be ineffective in shedding the bridge of ice. Studies done in the late 1990s have established that there are few, if any, documented cases of ice bridging on modern boot designs.”

An NTSB Safety Alert (SA-014 December 2008, revised December 2015) adds: “The Safety Board has no known cases where ice bridging has caused an incident or accident, and has investigated numerous incidents and accidents involving a delayed activation of deice boots. Ice bridging is extremely rare, if it exists at all. Early activation of the deice boots limits the effects of leading-edge ice and improves the operating safety margin.”

I have met and had discussions with pilots on both sides of this fence. The reason I bring it up at all, is that if you have a modern aircraft with a timed boot system and the AFM says to activate the system prior to enter known icing conditions, there is no reason to wait for a certain amount of buildup to avoid bridging.

After a career as a Part 135 pilot, flight instructor and check airman, Ryan Motte recently got hired by a major airline and is now flying as a Part 121 first officer.

One part of the King Air which has a less than positive effect when iced up are the stall trips on the leading edges. Not only is their presence required to control the handling of the aircraft on landing but they are also required to be present for certification (initial out of the factory, as well as after any maintenance activities in which they get disturbed) – they are also not located in the same spots from left to right because of the airflow over the wing being not identical between LH and RH wings and thus an airworthiness concern if missing or incorrectly located .

When attached to a de-ice boot, the ice may come off of the stall strip but these little strips of rubber which are less than 1/2″ in cross section and anywhere from 10-14 inches long are neither heated nor typically the focus of any special cleaning and ice-shed product application. If they don’t shed ice or if one sheds ice but the other does not you may find the landing “a bit squirrely”,

Hey Steve,

That is super interesting! The PC-12 had similar stall strips if my recollection is correct, which may explain the substantially higher approach speed and required partial flap landings with ice on the airframe. You would be in “pusher ice mode” when the prop heat was on and the inertial separator was opened, which had you crossing the threshold at a ref speed of 95-100 knots and flaps 15, depending on weight. Compared to flaps full and around 80-85 knots, the landing distance was increased dramatically.

I’m sure the issues you mentioned with the stall strips were a contributing factor in this design, since having them iced over certainly mitigates their effectiveness.