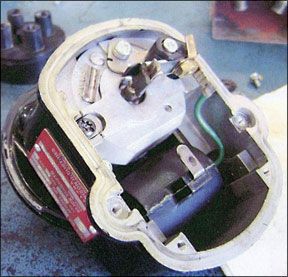

Cessna 172/180/185 Control Yoke Corrosion Transport Canada (TC) in late 2009 issued a Service Difficulty Alert detailing failure of a parked aircrafts control yoke that broke during high-wind conditions. A complete fracture occurred between the yoke pivot area and the elevator attachment point due to severe internal corrosion. A 2001 288 Cessna service bulletin provides instructions for creating an inspection hole, recommending annual inspection and corrosion treatment. Cessna 208B Grand Caravan Corroded Flap Bell Crank Bolts During routine inspection, the outboard-most flap bell crank Part Total Time(s): (unknown) Cessna 340A Broken MLG Door Idler Bellcrank On pre-flight inspection, right main inner gear door was open. Discovered idler bellcrank to inner gear door broken. After installing a new bellcrank, up and down tensions were checked. Inner gear door down lock tension was found above manufacturers specifications. Part failure possibly due to excessive tension. Part Total Time: 4439 hours. Cessna Citation X Disconnected Flap Linkage On visual approach, the co-pilot complained the aircraft was out of rig and wanted to roll right with flaps at 35 degrees. On inspection, the right flap was discovered fully extended and its drive linkage was disconnected. Part Total Time: 6098.0 hours TCM Cylinder Missing Seal Counterbores While performing incoming inspection of a new TCM cylinder (p/n 655484A5) for an IO-550, the cylinder pushrod housing boss was found not to have been machined for its seal. Part Total Time: 0.0 hours Slick Magneto 4370 Failed Gear Shaft The magneto was inspected after excessive engine RPM drop during run-up. The technician found the gearshaft failed at the base of the slot retaining the points cam. When removed from the cam, one side of the shaft stayed attached to the gear. Part Total Time: (unknown)

(p/n 2622091-1) was found corroded and frozen. The bolt was frozen to the bushing (p/n 82614-4-100N), preventing the bolt from rotating inside the bushings and elongating the mounting brackets (p/n 2622101-3) bolt hole. When the flap handle was selected “up,” the cable would wrap around the bell crank, causing high cable tension.