Anyone who paid attention to news coverage during the early stages of the Covid-19 pandemic likely is familiar with the term “personal protective equipment,” or PPE. In the medical profession, PPE can include masks, gloves, gowns, booties and more. But PPE isn’t only for doctors and nurses.

Construction workers wear hardhats, steel-toed boots and Day-Glo vests. Many motorcyclists have adopted the initialism ATGATT, for All The Gear All The Time: helmets, boots, gloves, leathers, whether riding on the street or off-road. No shorts, flip-flops and tank-tops, even if it’s only a quick trip to the corner store. Motorcyclists refusing to wear helmets often are referred to as “organ donors” behind their backs.

What does any of this have to do with flying? A lot actually, since the machines we operate aren’t designed with crashworthiness uppermost in mind. Of course, Job One is to not crash, but sometimes stuff happens. And when stuff does happen, there’s little time to don a helmet or gloves. How can we integrate PPE into our higher-risk flying, and be better prepared when something happens?

It’s The Mission, Silly

It’s important to understand that stuff happens more often when we’re on some sort of mission other than chasing $100 hamburgers. If we’re flying a for-real warbird, an experimental on its first test hops or even a tried and true airframe with a brand-new engine, for three examples, the risks go up. They also go up when performing aerobatics, surveying, flying pipeline patrol or applying agricultural chemicals at low level.

Crashworthiness

The airplanes we fly are hollow, with items like engines, instrument panels, fuel tanks and human beings taking up some of the space within the aluminum, composite or fabric-covered structure. The wings, empennage and most of the fuselage are filled with air, which isn’t known for its resistance to deformation or ability to absorb the kind of energy generated in a crash. And the structures typically aren’t optimized to have crush zones designed to absorb that energy instead of transferring it. In other words, they aren’t your family’s new SUV.

Even the latest airplanes meeting updated FAR Part 23 certification standards still have fuel lines running through portions of the cockpit and under the floor. In older models like Piper’s Cub and Aeronca’s Champ, the fuel tank is mounted above the pilot’s feet, between the firewall and the instrument panel. They, like my Beech Debonair, left the factory with plywood floorboards.

But flammability is only one thing to worry about in a crash. Instrument panels typically are made from stout sheet metal, helping to stiffen the airframe, and are adorned with all kinds of knobs and switches, some of them directly in front of the front-seaters, and well within range of our foreheads when coming to an abrupt stop and wearing only a lap belt—probably many three-point harnesses, too. The control yokes are mounted to horizontal tubes protruding from those same instrument panels, aimed at our torso. (I’m old enough to remember when Cessna added padding to the yokes.)

There are exceptions, of course, including the Cirrus line and others with sidesticks instead of yokes, knee bolsters instead of sharp metal. And instead of strategically placed knobs, like on the attitude indicator at upper right, the flight instruments often are video panels. That simplifies relocating things like toggle switches and other knobs, also a plus for modern designs. Airbags are another newer feature, which help reduce flailing in a crash and may be retrofitted to other airframes via installing new harnesses.

Helmets

According to the NASA Langley Research Center’s Small Airplane Crashworthiness Design Guide, “Helmets are a very effective delethalization device. They provide protection from point loading

and have a self-contained energy-absorption system.” The Guide notes, however, “it will take a major change

in public acceptance before helmets become common in light airplanes.”

Reasons to wear a helmet should be obvious. What might not be so clear is one of the main reasons warbird pilots, cropdusters and others wear helmets routinely: They’re in a relatively tight space where abrupt maneuvers or even turbulence can cause their head to hit a canopy or other structure. One moral to the story is it doesn’t take a crash for a helmet to prove its worth in many flight operations.

In addition to protection during a crash, helmets also offer everyday benefits, especially in open-cockpit aircraft. For one, helmets designed for aircraft typically have provisions for a separate headset or a built-in system, often simplifying communications and the equipment required. They also may incorporate adjustable visors, eliminating the need for sunglasses, and providing additional protection in a crash.

Helmets also offer at least some degree of fire protection. That falls down, of course, when wearing an open-face helmet without some separate face protection, which we’ll come back to in a moment. Downsides of wearing a helmet include their weight, which can become problematic in turbulence.

Many aircraft are still flying around today with only a lap belt and a friction lock to keep it in place. Several years ago, the FAA adopted policies to facilitate installing multi-point harnesses in aircraft by providing ways to reduce the paperwork burden. Airframe manufacturers may offer complete kits, with the necessary approvals. If you’re still flying under only a lap belt, obtaining FAA approval for multi-point harnesses should not be a barrier to installing them.

Fire

And now we get to the real reason to consider what we wear in a personal airplane. Again according to the Small Airplane Crashworthiness Design Guide, a 1998 safety analysis of 68 general aviation accidents revealed that 22 percent of the crashes involved post-crash fire, with fatalities in 48 percent of them. “The crash scenarios evaluated in the study were selected to approximate the limits of survivability, and the statistics obtained from their analysis suggest that although there are not a large number of GA aircraft crashes involving post-crash fire, the accidents that do involve fire are extremely life-threatening for the occupants.”

Separately, NASA Langley’s Guide adds that “an occupant’s ability to survive these fires is usually predicated on the clothing they are wearing, the air they are breathing, the temperature to which they are being exposed, and the duration of their exposure.”

The typical flight suit worn in cockpits is made from a single layer of flame-resistant Nomex, a trademarked “wonder” fabric in use for various applications since the 1960s. Nomex has excellent flame resistance. Flame resistance is not the same as flame-retardance, which is less effective and often achieved by chemically treating common materials like cotton.

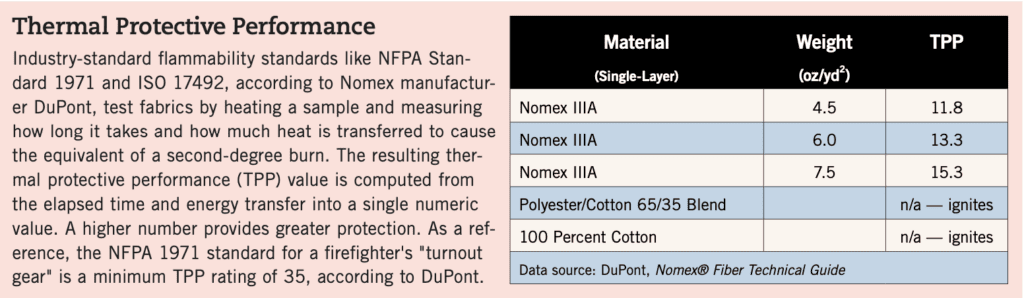

How effective is Nomax at keeping the wearer protected from fire? It depends, on fabric thickness and layers: a single-layer Nomex garment is less effective than a multi-layer suit. The sidebar and table above present one way to assign numeric values to the flammability of Nomex versus common clothing fabrics.

Complete protection from a post-crash fire is elusive. In addition to a multi-layer flame-resistant flight suit, we need to think about both what’s under it and how we can protect extremities.

Gloves and socks made from Nomex are widely available, as are undergarments. Both should be considered part of a comprehensive approach to wearable fire protection. Footwear is another matter, and fire-resistant examples don’t include sneakers or dress shoes. The final extremity is the head, and helmets certainly can provide some fire protection, but that’s not how they’re optimized or rated. They also may contain flammable materials. In any event, a Nomex balaclava seems a necessary addition to a comprehensive fire-resistant wardrobe.

Poster Child

High-energy crashes of vehicles aren’t restricted to aviation. Formula 1 racing has contended with risk mitigation for decades, evolving a comprehensive set of driver-safety equipment standards, including fire protection. The F1 standards got their acid test on November 29, 2020, during the first lap of the Bahrain Grand Prix, when the race car driven by Romain Grosjean impacted a track-side barrier at 119 mph, subjecting him to an estimated 67 G. The impact split both the barrier and the car.

A fire erupted. Although personnel responded immediately, their lack of equipment delayed Grosjean’s extraction. Grosjean, however, managed to extricate himself from the wreckage and walk through the flames to safety. It took 28 seconds.

The Halo head and neck restraint is widely credited with preventing any serious injury, and Grosjean’s multi-layer suit limited burns to his hands and ankles. He returned to racing in 2021.

Walk into the typical pilot’s lounge wearing a military-style flight suit, carrying a helmet, and you’d better have arrived in a crop duster, a P-51 or an EMS helicopter. Otherwise, you might be facing some interesting questions. At least in part, that’s because pilots seem to pride themselves, rightly or wrongly, on their ability to leave the ground and come back to it without major drama, in a shirtsleeve environment, similar to those we’re grown accustomed to on an airliner. Airliners aren’t towing banners or dusting crops—contrails are not chemtrails—so there are differences.

At the same time, it might not be the most confidence-inspiring thing when we show up for an Angel Flight or Young Eagles event carrying a helmet, and wearing fireproof clothing, gloves and a balaclava.

Jeb Burnside is this magazine’s editor-in-chief. He’s an airline transport pilot who owns a Beech Debonair, plus the expensive half of an Aeronca L-16B/7CCM Champ.