During the initial phases of my private pilot training, something I struggled with was overusing the flight instruments. Rather than use external references like the horizon and a visual point for something like steep turns, I would fixate on the attitude indicator and altimeter. After all, how could I tell if my altitude was off if I could not look at the altimeter? Eventually, my instructor covered the instruments one by one while I was doing maneuvers, and lo and behold, everything improved! Not only was using the attitude indicator not required, in many ways it was less precise than proper visual flying.

Start your instrument training, and suddenly those same instruments are vital. Not only should you be using that attitude indicator as a central scanning point while instrument flying, but it is required equipment under IFR. An attitude indicator failure in VFR flying is a minor inconvenience whereas the same failure in IMC constitutes an emergency. If you have experienced a gyro instrument failure in IMC, you understand why.

SIX-PACK PANELS

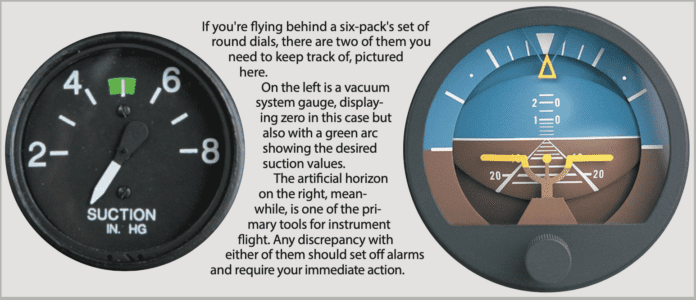

Let’s first consider the standard six-pack layout of mechanical, so-called “steam” instruments, with the promise I’ll get to glass panels in a moment. In the standard six-pack, with two rows of three dials, the two middle instruments are the attitude indicator with the directional gyro below. This layout also can have glass instrumentation for just these two instruments, driven by an electronics box called an AHRS (attitude and heading reference system), or other variations of analog and digital dials.

If your training was similar to mine, at some point while learning instruments, your instructor stuck up a Post-It note (or applied a suction-cup instrument cover if they were really fancy) over the attitude indicator and DG and declared it partial panel. I often reflect on the difficulties and limitations of flight training, especially where simulator use is extremely limited. This is a classic example, because the instrument will not always hard fail, and it certainly will not do you the courtesy of covering itself up.

The AI or DG could fail individually, or a vacuum pump failure could knock them both out. A flag could display, or the instruments could start tilting or even tumbling without a warning. The most important strategy in mitigating risk from failed gyroscopic instruments is the same as any other failed instrumentation, ensuring an effective and consistent scan. If just the attitude indicator begins to tilt erroneously, you can cross reference with changes to the DG and compass heading, as well as the turn coordinator.

This works for the DG as well, if the heading is drifting while the turn coordinator, compass and AI indicate straight-and-level flight, obviously there is a one-sided disagreement. This is easy to discuss while comfortably reading Aviation Safety magazine, with two feet on the ground instead of while when task-saturated flying an airplane.

I have experienced an insidious failure of an attitude indicator in IMC, and to say it was extremely disorienting is an understatement. While trying to overcome the “leans” created by my brain wanting the attitude indicator to show level flight, I had to keep the flight path aligned using the remaining instruments. Eventually, I was able to do this, but it was a struggle.

Once I confirmed the failed instrument, I covered it and continued. In my opinion, this is the most dangerous part. VFR into IMC accidents end up with pilots disoriented and can lead to accidents in minutes, if not seconds. While instrument-rated pilots are generally more trained and proficient in IMC, a gyroscopic failure can be disorienting enough to cause a loss of control.

GLASS COCKPITS

Glass cockpits have advantages in these kinds of failures, because generally they can detect and annunciate it for you. Different types of failures can present themselves, such as screen failures. The attitude indicator/artificial horizon technology may be fine and dandy, but if the screen cannot properly show the display, it’s useless. Additionally, some glass cockpit and AHRS units will show symptoms before a hard failure occurs. Screens may turn fuzzy, or red “Xs” may appear briefly. Knowing what the annunciations mean is a great mitigation strategy. With EFBs more prevalent than ever, tucking away an electronic manual on it for your avionics package can be extremely informative.

Many avionics packages that include some glass have helpful mitigation strategies. You may be able to swap screens if there is a failure or choose a backup source for AHRS input. Some AHRS and glass setups contain a reversionary mode that will combine multiple screens’ worth of information onto non-failed screens. The worst-case scenario typically is flying with a backup AI/DG/turn coordinator, hopefully not placed too far outside your typical scan.

Since knowledge is power, I strongly recommend having a good understanding of these functions. A severe degradation of instrumentation in IMC is an emergency, and it should not be the first time a pilot is considering how the screens work. For practice, on a clear day, try shooting an approach or two on just the backup instruments. It can be very challenging, and something many pilots do not stay proficient on.

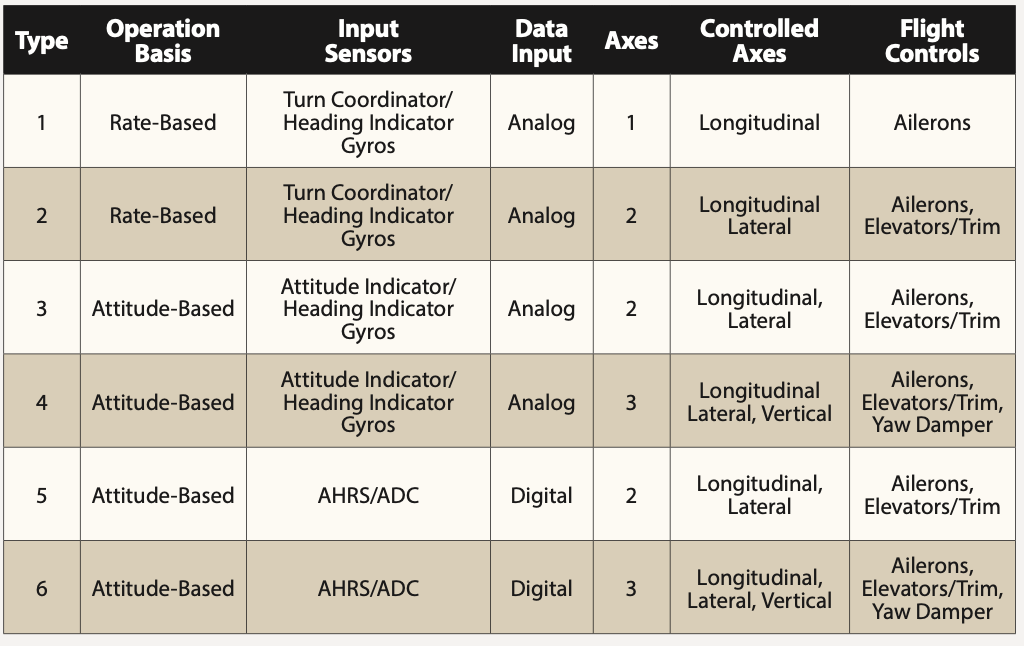

Since more and more GA aircraft have glass cockpits, flight directors and autopilots, it’s worth discussing what happens when gyroscopic instruments fail with higher levels of automation. I have flown planes with autopilots from the 1970s that perform vastly different from modern autopilots, so this is very general and should be verified by your POH and any associated avionics manuals. If there is an AHRS failure, or any failure that knocks out multiple gyroscopic instruments, it is safe to assume the autopilot and flight director will not work. If the aircraft has multiple AHRS, swapping between them will likely disconnect the autopilot. This is a great exercise to practice in VMC in a low-workload environment.

I once flew an aircraft that had two AHRS systems, and when you swapped them, the autopilot did not actually disconnect. It almost did something worse, though, which was swapping into pitch and roll mode. So the aircraft was happily flying along without guidance, which may not be immediately apparent to the pilot right off the bat. Knowing what to expect when troubleshooting this can save everyone the trouble and keep situational awareness high.

SITUATIONAL AWARENESS

So, you have properly identified and mitigated a gyroscopic failure, whether by covering the instrument or working the magic with glass, and the shiny side is still up. Now what? If you are anything like me, you spend a good portion of cruise flight monitoring conditions and thinking ahead. It’s basic situational awareness..

A good rule of thumb is if we are flying together and I ask, “Where would you go right now if we had an issue?” there would be a general understanding of the aircraft’s location and the nearest suitable airports and landing options. Sometimes there are not suitable options nearby, and that should be acknowledged. Long story short, I would seriously consider diverting after a gyroscopic instrument fails. This is hugely situational, and why ADM is so critical to safe flight operations.

Some scenarios include: Failed attitude indicator, with no backup: I would personally consider diverting to the nearest suitable airport with a precision (or precision like, for you WAAS-equipped pilots out there) approach. Most airports with an ILS or LPV have decent levels of service, and following a three-degree glideslope down to the nearest runway minimizes the risk of disorientation.

It will be a simpler approach briefing and setup, and most of my recently flown approaches are precision, so I feel most comfortable in that realm. This may not apply to you, which is why your ADM definitely should consider your experience, equipment, fuel, weather and any other factors that may be relevant.

Failed AHRS, functional backups: This could go any number of ways. If the avionics layout promotes a decent scan while on backup instrumentation, I might elect to continue, depending on the time/distance to my destination, as well as the weather. If this is soon after departure, the safest choice may be returning to the departure airport, especially if you are familiar with the approaches.

Long story short? Make good decisions. Once airborne, never nurse a sick aircraft to the destination or a maintenance location. Rather than focusing on the inconvenience, instead try to think of the new adventure on which you’re about to embark after a safe, conservative decision. I have diverted many times, and I do not regret a single one. This dovetails nicely into my final point for flying with any failed equipment affecting the flight’s safety.

Use any and all resources. I have heard people express concern with bothering ATC, or not asking for additional assistance due to paperwork. The ATC system is built for exactly this situation, and in the unlikely event that paperwork will be required, it is a small price to pay. I have declared emergencies for failed instrumentation, and I filed an ASRS report for the data point and that was it—no fuss, no muss. Passengers also can assist, especially if they are frequent fliers. Good CRM, even single pilot, can do wonders in mitigating the threat from failed equipment.

I admit, it has been a couple of years since primary instrument training for me. While doing some research, I decided to review the required equipment for IFR flight, which includes a number of items listed in this article. The regulation itself is FAR 91.205(d), which is always worth a quick review. A handy acronym for this is GRABCARDD, which helps explain this sidebar’s silly header. “GRABCARDD” stands for:

G—Generator (or alternator—the source of electrical power)

R—Rate-Of-Turn indicator

A—Attitude Indicator

B—Ball (referring to the inclinometer)

C—Clock (needs to display hours, minutes and seconds)

A—Altimeter

R—Radios

D—Directional Gyro or Heading Indicator

D—DME (above FL240)

In the eyes of the FAA, if something is not working 100 percent of the time, it is inoperative. This can be a challenging mindset with keep up with, especially if you are paying the maintenance bills. With the above equipment, however, it is always better to be safe than sorry. If something seems off or you notice an intermittent issue, it is worth convening with maintenance.

MITIGATION, DETECTION

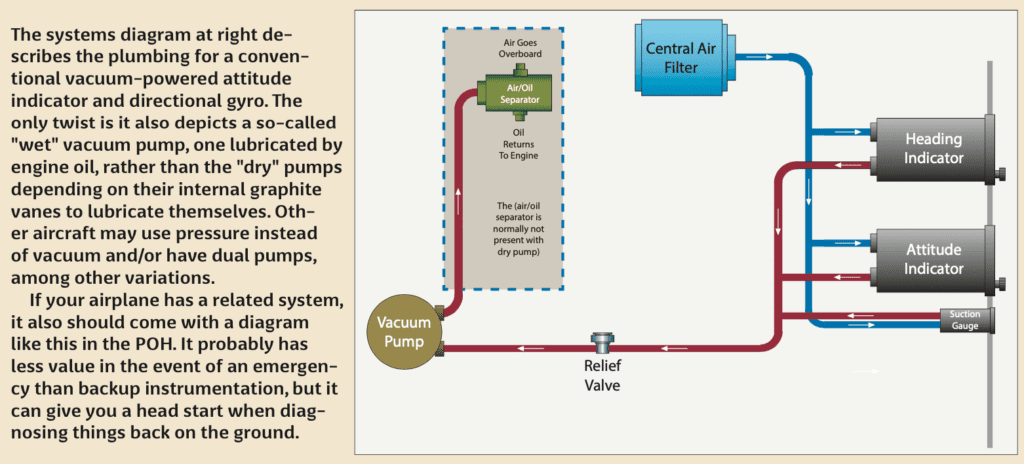

I discussed a few of these in a similar article regarding the pitot static instruments, so my apologies if there is some overlap. Knowing how your systems work is a great start in early detection of potential failures. For example, your POH may have a procedure written for testing the vacuum system pressure on the ground, which can be a means of early detection of malfunction.

Often, the gyro instruments are designed with redundant power sources. In the aircraft I trained in, the DG and AI were vacuum-powered, but the turn coordinator was electrically powered. Regardless of how it’s configured, knowing what will be functional and what won’t is helpful when assessing system failures. Performing a proper instrument taxi check can save you from departing with faulty instrumentation and is a great habit for all instrument pilots.

Last, and certainly not least, is always maintain proficiency. I practice partial-panel flying any time I have a good opportunity. Even on a clear day, I will load an approach and simulate a failure. I may cover my AI and DG and see how to optimize my scan.

If I do not feel comfortable and want additional practice, I make a point to work in additional scenarios. The FAA is strongly emphasizing personal minimums, and I think this is a great situation where dynamic personal minimums come into play. In the above situation, if I feel the need to gain some proficiency, maybe I raise my personal minimums to 1000-foot ceilings with good visibility underneath until an instrument proficiency check or at least until I have more opportunities to practice.

Just like most aspects of aviation, trust, but verify, your instruments. If you fly long enough, one will probably fail. Risk mitigation strategies, good ADM and a proper scan can help keep the blue side up until everyone is safely on the ground.

Ryan Motte is a Massachusetts-based Part 135 pilot, flight instructor and check airman. He moonlights as Director of Safety when he isn’t flying.