Way back in the mid-1980s, when I purchased a 1946 Cessna 120—the same week I earned my private pilot certificate—I received my taildragger checkout from Mr. W.E. Dierking in Higginsville, Mo. “Dirk” had taught U.S. Navy cadets in Waco biplanes during WWII, and he sure taught me a lot about flying! One of the techniques Dirk suggested was to take off with the fuel selector on the left tank (there was no “both” position in the ’46 Cessna), fly for an hour, and write down the time aloft. Then, switch to the right tank and fly until that tank ran dry. As the engine hesitated, switch back to the left tank; you would then know you have the amount of time you’d flown on the right tank minus one hour until you ran out of gas. I never flew the 120 far enough to need this technique, and I never tested my ability to restart the engine after intentional fuel starvation in flight. In recent years, the technique has gained limited but vocal support among personal airplane pundits on the internet and those who follow their guidance.

But was it a good idea? Occasionally this question comes up in seminars I present. Typical pilots tell me the idea of intentionally running a fuel tank completely dry in flight is dangerous and absurd. Dirk also told me to use a chandelle to get out of flying up a blind canyon—a technique with possible merit—and that if you’re VFR only or flying a VFR airplane and are caught on top of a solid cloud deck, that you should enter a spin, spin down through the clouds and recover once you’re in visual conditions below them. That’s perhaps not the best strategy for dealing with that challenge, in my opinion, and two out of three isn’t bad. So just because the old-time pilots apparently ran fuel tanks to engine failure in flight all the time, does that make it the best technique in the modern world? Let’s look at some of the pros and cons of running a tank dry in flight, so you can make an informed decision for yourself.

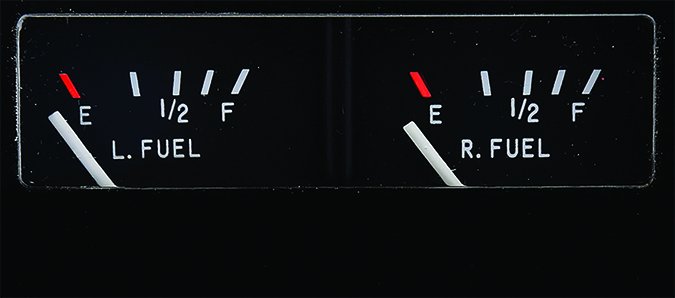

Fuel Gauges: Can You Trust ‘Em?

Probably no other airplane system is so universally discredited by pilots than the fuel quantity indicators. There’s a widespread misconception that fuel gauges are “only required to be accurate when there is no fuel in the tank.” Guess what—like a great many other “old-wives’ tales” in aviation, this is wrong. Where does that “only accurate when empty” misconception come from? It’s from a partial reading of FAR 23.1337. The passage often quoted alone, out of context, when making the claim that fuel gauges are not accurate at any other time is:

Each fuel quantity indicator must be calibrated to read “zero” during level flight when the quantity of fuel remaining in the tank is equal to the unusable fuel supply determined [during aircraft certification].”

Some airplane owners use this to conclude that it’s useless(and unnecessary) to invest time and money into calibrating gauges that do not indicate properly. But as I said, this is quoted out of context. Instead, the first part of 23.1337(b) tells us:

There must be a means to indicate to the flightcrew members the quantity of usable fuel in each tank during flight. An indicator calibrated in appropriate units and clearly marked to indicate those units must be used.

What about airplanes certificated to the old Civil Air Regulations Part 3, the body of regulations later superseded by FAR 23? The certification standard of CAR 3 airplanes requires that the fuel quantity indicators be accurate in flight as well as at the “zero usable fuel” level.

Active GA pilot and retired TWA Captain Tom Rosen had a great point: It’s less important to know when your fuel tank is empty than it is to know accurately when it is only full. This gives you time to do something about fuel state before anything becomes critical. If your airplane’s fuel gauges aren’t accurate and reliable, fix them. Not only is it required by the regulations, it’s also an important component of fuel monitoring that helps prevent all-too-frequent fuel-related crashes.

Pros

The modern advocates of running fuel tanks dry in flight usually support their belief with these substantiations:

Maximizing Range: Pilots who promote flying tanks until fuel starvation, except of course the last tank containing fuel, primarily do so to maximize the available range of the airplane. Most light airplanes carry five to seven hours of fuel with full tanks at normal cruise power settings and fuel burns. I know extremely few pilots who are willing to endure a non-stop flight of that duration behind the controls of a small airplane. Among those who say they are willing, virtually none actually ever do so, and even then only rarely.

More often, pilots want to fly two-to-three-hour legs with a full cabin that requires less fuel be carried. If you indeed actually intend to fly a maximum-endurance trip, you’ll need to get the most fuel possible out of each tank, and arrive near your destination with enough remaining in the last tank you select to get you on the ground and, if needed, back up to cruise flight and to an alternate destination.

Knowing Where The Fuel Is: Part of the “maximizing range” argument is that by successively running tanks dry—assuming you have two or more independently selectable fuel tanks—you’ll know that eventually all your remaining fuel is in the single tank you’ll use for landing (and go-around/missed approach/diversion if needed). A corollary to this is that you end up with a lot of fuel in one place, instead of a little fuel in a lot of places, none of which can independently fuel your engine(s) to landing.

Mastery Of Fuel Management: Advocates of running tanks dry routinely report they have mastered their airplane’s fuel management to the point they can anticipate within minutes (or less) when the engine will quit from fuel starvation. These pilots say they can anticipate when the engine will hesitate and be ready with their hand on the fuel selector to move it at the first “twitch” of the fuel flow or pressure, or the first burp of the fuel-starved engine.

Utility: The overriding justification for intentionally running tanks dry in flight is to eke the maximum utility from the airplane—to fly it as far as possible, sometimes just to say you have done so. Some call this maximum efficiency, but this assumes the pilot has a clear need to fly the airplane to its maximum fueled range.

Cons

Likewise, there are a number of reasons not to intentionally run fuel tanks completely dry in flight.

The Accident Record: The GA aircraft accident history is filled with cases of fuel starvation that ended in an off-airport landing (or worse, a crash) when the pilot did not or could not get the engine restarted on a tank that still contained fuel. We’d also bet some engine failures involving multi-engine airplanes actually involve fuel starvation. AOPA tells us that fuel mismanagement accidents happen about twice a week in the U.S., and roughly half of those are fuel starvation (the others half being fuel exhaustion, running completely out of gas).

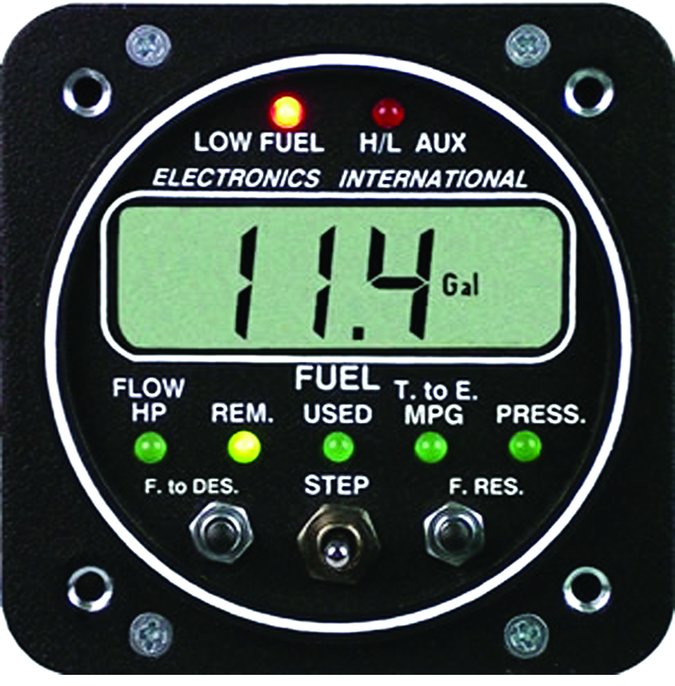

Australia’s Transportation Safety Bureau notes that the rise of fuel totalizers and GPS navigation has occurred at the same time the rate of fuel exhaustion accidents has decreased dramatically. However, the fuel starvation rate has remained unchanged. Cockpit fuel monitor technology can tell you how much total fuel is on board (assuming you input the data correctly), but it’s still up to the pilot to determine which tank the remaining fuel is in. There’s no avoiding the fact that fuel starvation is a common cause of engine failure that results in a crash, often fatal.

Unacceptable Altitude Loss: I’m amazed that some proponents of running fuel tanks completely dry as a normal procedure report “I only lost two or three hundred feet before the engine restarted” as an acceptable consequence, even when on an IFR flight.

Pilot Error: Pilots who advocate running tanks dry argue, perhaps successfully, that a pilot who does this as a matter of routine will not panic and will know precisely what to do if he misjudges the fuel burn and a tank runs dry sooner than expected. However, history shows that distraction can negatively impact the performance of even highly experienced pilots. Avoiding running a tank completely dry before switching away to another tank ensures you won’t have an immediate, time-critical need to switch tanks at some point when your workload is high or something else is demanding your attention.

Vapor Lock: The reason engines don’t always restart after a tank is run completely dry is that some fuel system designs may develop a vapor lock in the lines before the switch-over to another tank is complete. This is prevalent in airplanes with auxiliary fuel tanks that feed directly to the engine(s). In some airplane types, there is documented evidence that running an auxiliary tank dry can make it hard to restart the engine on any other tank. For example in the airplanes I commonly fly, tip tanks in Beechcraft Bonanzas and in-wing auxiliary fuel tanks in early Bonanzas and Barons are known for this fuel system characteristic.

Contamination In The Sumps: Another argument against running a tank all the way to empty is that any contamination that settles in that tank’s sumps will be sucked into the engine. Many advocates of maximum-range flying note they are able to access even the “unusable” fuel in flight (see the sidebar on the opposite page). Although advocates dismiss the potential for drawing contamination into the engine, this is inconsistent with the common assertion that there is no real “unusable” fuel in their airplanes.

Testing Your Fuel Capacity

As an owner/operator, it’s probably a good idea to determine how much fuel your airplane’s tanks actually hold. A common method is to run a tank completely dry in flight, then land and fill it to see how much fuel will fit.

Theoretically this tells you how much fuel you can access from that tank in flight. If pilots conduct this test, they should approach it as the experimental test flight it is. Plan it so the airplane is over an airport when the fuel runs out, so you can glide to a runway if the engine doesn’t restart.

A clever student of mine made an even better suggestion: Fly until the tank is nearly empty, then land on a fuller tank. After landing, switch back to the nearly empty tank and run the engine until fuel starvation. This method completely avoids the possibility of in-flight engine stoppage.

This test does not account for important variables, including temperature. We know avgas expands with heat, for instance, because when fuel gets hot in airplanes on the ground it expands and some vents overboard. The airplane must be precisely level when fueled before and after the test.

In many airplanes, internal bends or baffles, or multiple-cell fuel tanks filled through a single port, the speed at which fuel is added to the tanks also is important.

Limitations

If you’re going to run a tank dry, first pay attention to the airplane’s fuel system and any limitations it imposes. These generally involve which tank(s) to use for takeoffs or landings, and specify using either the fullest tank or both. Obviously, you can’t draw fuel from a single, specific tank if your fuel selector doesn’t allow it. Equally obvious, don’t try to run a single tank dry with the selector on “both.”

Other limitations may apply regarding imbalances when one tip or auxiliary tank is full but another’s empty. Even if nothing’s published, you may want to add a couple of knots on approach to ensure roll control at low speeds is adequate to keep imbalanced wings level.

Finally, altitude is your friend. It’s one thing to run a tank dry at altitude; it’s quite another to knowingly run it dry while maneuvering for an approach or in the traffic pattern.

Run it Dry?

My opinion is there’s rarely an operational need to run a fuel tank completely dry in flight. History shows there’s a very real chance of not being able to get the engine restarted. And even if the engine does restart, the airplane may lose enough altitude in the process to trigger ATC altitude deviation alarms.

If you are so attuned to your airplane’s fuel load and fuel burn that you can anticipate within a few minutes when the selected tank will run dry, you have the fuel state awareness to switch tanks a few minutes before the engine hesitates from fuel starvation. If the few ounces of fuel that remain in the tank when you do this impact your ability to make it to destination, I submit that you have larger risk management issues to overcome.

On those rare maximum-endurance flights, I run tanks down to about 1/8 capacity at the lowest on one and tank on the one used for landing and—if needed—go-around and diversion. In the late-model Beech Bonanzas I routinely fly, 1/8 tank is about four gallons of usable fuel remaining—not enough time-in-the-tanks to change a go/no-go decision, but sufficient at a low power setting and lean-of-peak EGT for an emergency 20-to-30-minute reserve if fuel in my fuller tank suddenly becomes unavailable because of a plugged tank air vent or some other abnormality.

I know a couple of pilots who routinely fly light airplanes across oceans or vast stretches of very remote territory. They accept the risks and fly each tank until the engine quits—except the last tank, of course. They have no choice, if they are to make the flight at all. For almost all of us, however, there simply isn’t a need to include pilot-induced engine failures in our standard operating procedures.

Tom Turner is a CFII-MEI who frequently writes and lectures on Aviation Safety.