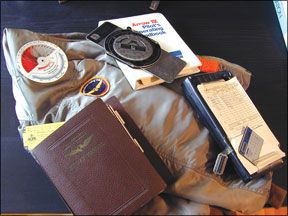

Every year, takeoffs and landings account for over half the pilot-related accidents, according to the AOPA Air Safety Foundation. While poor technique accounts for some of them, many accidents could have been prevented if the pilot had consulted available documentation to determine the airplanes performance. But before any of that can happen, we need to ensure we know how to evaluate current conditions. To assist students in determining performance data, I have them use a takeoff and landing data card on which is all the information a pilot should need to evaluate 288 takeoff and landing performance. The card is also useful for instructors who are in the position of flying multiple aircraft models or versions. As an example, in a recent period I flew four different versions of Cessna 172s (one with the airspeed in MPH, another in knots, a third with the 180-HP STC and still different V-speeds; the fourth was a Thielert diesel conversion-you get the idea). Keeping the numbers straight for these and other different airplanes can be a challenge without a reference card. Lets look at whats important to evaluate, and how to go about assembling your own data card. Weight The first item is to evaluate weight and balance, factors directly affecting any aircrafts performance. That an overloaded airplanes performance will decrease as its fuel consumption increases should not be news to any pilot. Too, one loaded outside its center of gravity (CG) range will handle differently, and will likely be dangerously unstable. In either case, the plane will not perform in a predictable manner and the pilot is in uncharted, dangerous waters. Step one is to get the aircrafts empty weight and moment. This sounds simple and straightforward, but I have seen incorrect aircraft weight sheets in logbooks. When I went back and checked the maintenance logs, I found a difference of over 200 pounds. Airplanes of the same make and model do not weigh the same. Dont forget basic empty weight consists of the aircraft, unusable fuel and oil. Unless carefully planned, its entirely possible for an aircraft to be within CG at takeoff and, as fuel is consumed, be out of limits at landing. A good practice is to do a weight and balance calculation as if the plane had no fuel. Then fuel weight and moment can easily be added to verify the airplane will be within limits with the required fuel. And some aircraft have zero-fuel limitations, where all weight above a certain point must be fuel. Weather And Maintenance The next step in performance planning is to determine the weather. For performance planning, pilots will at least need temperature, altimeter setting and surface winds. With this information, plus the weight and balance data already obtained, and an appropriate calculator or E-6B whizwheel, they can perform the appropriate calculations. Often, however, pilots will only get the current temperature and pressure altitude, which can lead to some problems if the flight is delayed or they attempt to use early-morning data throughout a full day of flying. Ive seen temperatures at takeoff run 20 degrees C warmer than the temperature used to predict performance, which can lead to obvious problems if you want accurate data. The same applies to pressure altitude. Instead, pilots should obtain current weather data. If thats not available for some reason, use the maximum temperature and pressure altitude anticipated for the takeoff and landing locations. It goes without saying: Pilots should be able to decode a Metar and extract the information necessary for accurate performance calculations. Winds can also have an effect on takeoff and landing distance, as well as crosswind, and should be computed at this time. Again, do not just use the current winds-look at the TAFs, if any, for the worst-case winds forecast during the day. Finally, the airplanes maintenance status also can have an effect on performance-and safety. Pilots should be able to confirm the status of required maintenance inspections during preflight. Flight schools and FBOs have different methods of showing this, but it is something a pilot should be able to check. Ive had cases where Ive been told that the maintenance was “good to go” on an airplane, only to discover that it was not legal. While some maintenance issues may not affect performance, others will. The time to check is prior to flight. Performance Charts Now that we have all the data we need, its time to get down to the nitty-gritty-how will the airplane perform given the current conditions? The first step is to have the correct performance charts. This sounds straightforward, but airplanes with a more-powerful engine, auxiliary fuel tanks or other modifications may lack appropriate charts reflecting the revised power or maximum gross weight. Sometimes, pilots will use charts from an information handbook for a generic 172 rather than the charts in the AFM/POH specific to the airplane being flown. The information may be the same, but then again, it may be different. Make sure you are using the correct charts for the airplane in question. Some AFM/POHs will have different performance charts for different weights, while many older models may only have a chart for maximum gross weight. Other manuals use density altitude in the performance charts (Piper products come to mind), while manuals for more recent models use pressure altitude (but are still “density altitude” charts since you compensate for non-standard temperatures). Either way, make sure you enter your chart at the correct pressure or density altitude-not airfield elevation. They may be different. It also is critical to look over any notes on the performance tables addressing things like aircraft configuration and how to adjust the charts for non-standard conditions, such as a wet runway, a grass strip or non-standard temperatures. Adjustments Its been said more times than we can count: Manufacturers performance charts are based on a new airplane, with a new engine, perfect rigging, properly inflated tires and a professional test pilot. Odds are, none of those variables will be the same for your takeoff. As one result, you should adjust the takeoff distance computed from the chart. To compensate, I recommend multiplying the takeoff distance result by 1.5 to get a “real-world” required runway distance. Again, this is for ideal conditions. As an added note, commercial operators need a fudge factor when computing takeoff and landing data, which may be one of the reasons they have a better safety record. If an airline pilot who does it on a daily basis uses a fudge factor, why shouldnt we? The table on the preceding page collects other fudge factors you may encounter together in one place. Some AFM/POHs will have charts for normal as well as short-field takeoffs; other manuals will only have charts for short fields. The takeoff data card shown above has blanks for both normal and short-field operations; if your aircraft manual is one of the latter, use only one of the takeoff columns on the preflight data card and be aware of the extra distance you will need if you do not use the short-field technique. Accelerate/Stop The next item in the Takeoff Performance table is one many single engine pilots may not be familiar with: accelerate/stop distance. Accelerate/stop distance is the distance required to accelerate a stopped airplane to liftoff speed, then reject the takeoff and stop the airplane on the runway. It is normally computed by multi-engine pilots prior to every takeoff (or at least it should be). So what does it tell a single-engine pilot and how do we compute it? Lets take the second part of this question first. Your AFM/POH already has the “accelerate” number: your takeoff distance. The distance required to abort the takeoff is taken from the landing charts distance to stop. Add these two numbers together and you have a close approximation of your accelerate/stop distance. This equips a pilot with knowledge that may help during a takeoff, especially if, for example, a door pops open at liftoff speed-what will you do, continue or abort? Knowing the accelerate/stop distance is greater than the runway is long, the best decision probably is to continue the takeoff and return for a normal landing to close the door. Now, presume something catastrophic occurs at liftoff speed from a short runway and you abort. You know you are probably going off the runway. Now you can execute a plan of action that you have thought out ahead of time: Perhaps going off one side and through a fence, rather than off the end of the runway and into a canal? Its better to make this kind decision in the comfort of the FBO lounge instead of when you suddenly realize the urgent need. By thinking about it beforehand, you may decide to offload passengers and/or fuel. Maybe youll reschedule. Maybe youll go home. Two final steps will complete your takeoff planning card: Write down V-speeds for your airplane and environmental conditions (we use VR and VRSHORT to denote normal rotation/liftoff speed and short-field rotation/liftoff speed, respectively). These numbers should come from the AFM/POH, not a checklist in the airplane. Then, write down the available flight time you should have at takeoff, based on the amount of fuel in your tanks after taxi and runup. Dont forget to note your takeoff time. Youll use this information later to know when you should be on the ground and when you will probably run out of fuel. Landing After completing the takeoff data card, filling out the one for landing should be a cinch. First, compute your landing weight. Unless you are staying in the traffic pattern, this may be quite a bit less than your takeoff weight. Next, compute your landing distance using meteorological data for your scheduled destination and arrival time. Remember: Temperature and pressure altitude may be much higher than when you took off. Then compute your V-speeds. VREF is your normal approach speed. VREF0 is your approach speed if landing with flaps retracted. VREFSHORT is your short field approach speed and VBESTGLIDE is, of course, your best-glide airspeed. Weight is important when determining landing distance. If there is only one weight listed for landing data in your AFM/POH, there is probably only one approach speed as well. If your gross weight is 2300 pounds but you are operating at only 1900 pounds, you will be carrying quite a bit of extra airspeed into the flare and float down the runway while dissipating this energy. Remember, approach speed is based on 1.3*VSO. Time for another rule of thumb: For every 10 percent of extra speed carried on takeoff or landing, increase required runway by 21 percent. While this may not be an issue on a long runway, in actual short-field situations, you may need to fly a slower approach speed. Some resources recommend reducing approach speed by half the percentage reduction in aircraft weight. Again, using the example of landing at 1900 lbs versus 2300 lbs, given an approach speed of 65 KIAS at maximum gross weight, your approach speed could be safely reduced to 60 (400 pounds is a 17-percent reduction in gross weight; half of 17 is about 8, rounded. Eight percent of 65 is slightly more than 5). Conclusion While all this might seem like too much work, most pilots can make these calculations in less than five minutes once they are familiar with the charts in the AFM/POH. There is a saying: Information is power. By calculating your airplanes takeoff and landing performance during flight planning, you are giving yourself the power of information necessary to make informed decisions prior to takeoff. Since an informed pilot is a safer pilot, thats a good thing.