Over the years, I’ve had my share of urgent situations, events that were abnormal and required ending a flight in a fashion other than was planned or performing a checklist from the flight manual’s emergencies section. These events never really turned into full-fledged emergencies, but “emergency” is defined by the person experiencing it. Most of us have experienced such episodes—peaking oil temperature, a rough-running engine, an unsafe landing gear indication. The outcome is more likely to be frustrated phone calls from unfamiliar airports, plus unscheduled underwear changes, than an accident report.

The last two such events I’ve experienced occurred in the same week. Both arguably resulted from flying airplanes that weren’t examples of pristine maintenance, neither of which was mine. But I learned a great deal from both of them, including the value of checklists and published procedures. But perhaps the most important lesson is that emergencies usually are not binary, either/or situations. Instead, they can be poorly defined, grow and dissipate in intensity, and present themselves in ways making them difficult to clearly diagnose. Because of all the “noise” they can involve, I‘ve come to think of them as analog events, not clearly comprising a one or a zero. Let me explain.

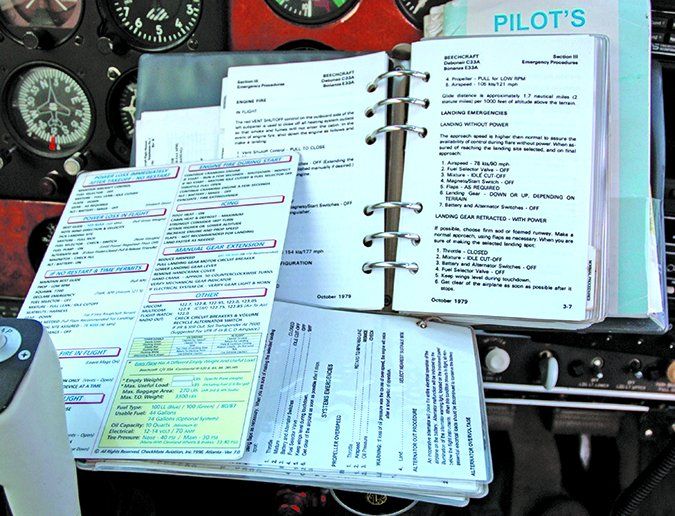

Paper Chase

I’ve been a flight instructor for many years, and felt it was time to get two other ratings, flight instructor instrument and multi-engine flight instructor. To accomplish my goals, I went to a local flight school specializing in the two ratings.

For the instrument instructor rating, I flew a Piper Arrow that had been experiencing high exhaust gas temperatures (EGT) on one cylinder. As a result, the operator was babying the engine but apparently was unable to resolve the problem. After talking with the mechanic, we changed induction seals on the offending jug and EGT readings came down to where they belonged. However, the airplane also was exhibiting relatively high oil temperatures. While checking to ensure the cold-weather baffling plate was removed, I noticed the oil cooler was caked with dirt and debris. As with the induction seals, cleaning the oil cooler brought the oil temperature back down to where it belonged.

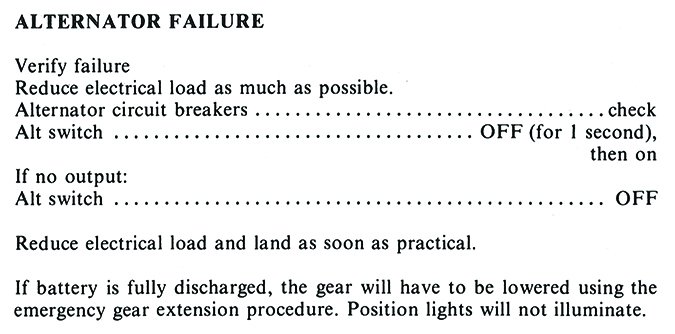

Having implemented solutions to the airplane’s known issues, I took off on a 30-minute hop to a nearby airport with another pilot receiving training. The flight went fine. On the way back, at about 1000 feet agl, I noticed the engine monitor was flashing 12.8 at me. Flashing is a bad sign, and by crosschecking with the ammeter, which was reading zero, I quickly determined the alternator had gone offline.

We were in excellent VFR conditions and could easily have returned to our destination, which perhaps would have been the most prudent decision. What I did instead was immediately put the gear down. I wanted to ensure it was down and locked while I still had battery power. Yes, I could have used the Arrow’s emergency gear extension procedure, but I view such as a backup, a choice to be used when there are no others. With the gear down, we started to shed electrical load.

Responding

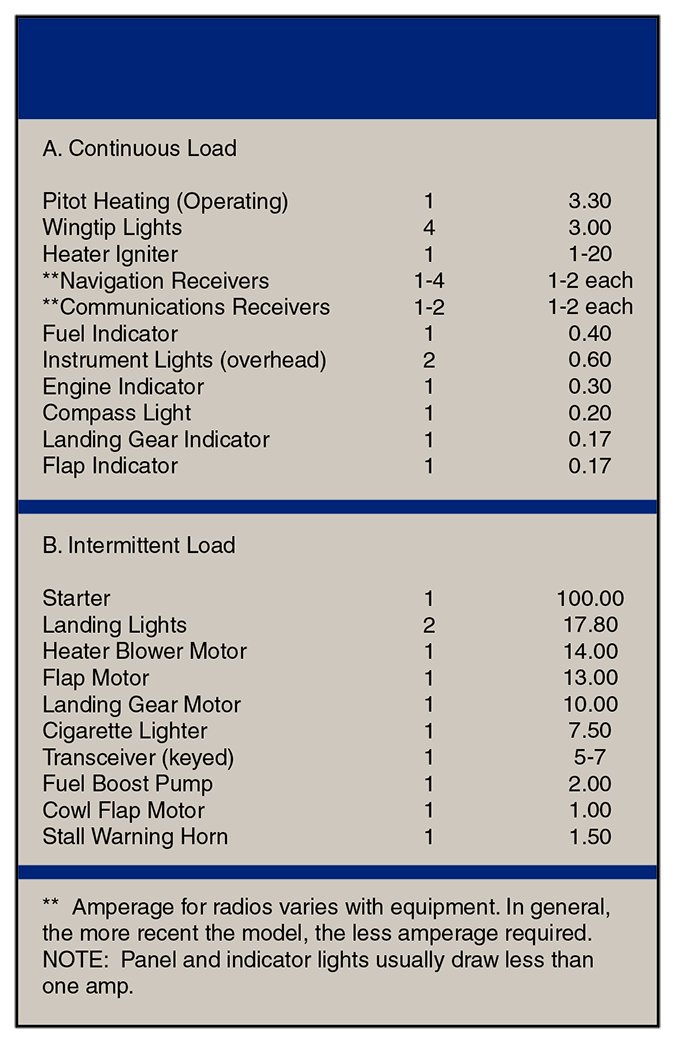

First, I turned off the transponder. Transmitting information takes a lot of power when compared to merely receiving it, and this step helps save what’s left of the battery. The next item to consider is pitot heat. Even though it was a good VFR day, I checked to make sure it was off—the system uses a relatively high amount of electrical energy to generate heat. Next, I turned off all the lights, the second Nav/Comm and the installed GPS (I had an iPad running my preferred EFB app in my lap).

With as much electrical load shed as reasonable, I contacted ATC, telling them I had an alternator failure. At this point, with the gear down, excess electrical equipment turned off and in communication with ATC, I reassessed the situation and noticed rising oil temperature. This Arrow had an STC’d cowling designed to reduce drag. One feature of the new cowling is smaller cooling inlets, which are great for cruising when the gear is retracted but not so good when it’s extended, the airplane is draggy and I’m running at cruise power.

The engine oil temp peaked at around 250 degrees F; too hot for my liking, but still under the 260-degree redline. This was a very strange situation: I had all the power needed to fly, but the more I used the hotter the oil got. If I flew more slowly, there would be less heat but also less cooling air. Ultimately, I was able to hold 100 mph at 1000 feet and got the airplane back to its base without further drama.

In The Air, Wishing You Were On The Ground

Generally, you can’t know the root cause of an emergency situation while you’re in the air. Yes, you know the engine is running rough, or the gear won’t extend, or the alternator is offline, and you even can try fixing the problem by, for example, finding the best combination of power settings or resetting the alternator switches.

Once on the ground and debriefing with the Arrow’s owner, he suggested I should have left the gear up and turned off the master switch to fly home. This was a possibility I considered but rejected. First, when I turn off the master, I lose all the radios and the ability to communicate with ATC; no one will know I am having trouble, where I am, or what is going on in the aircraft. I also lose the engine monitor—on an aircraft already experiencing two engine temperature issues on the same day—along with the rest of the installed gauges.

Such a plan also counts on the electrical system working again when I turn the master back on, and there being enough battery power to lower the gear when I get to the airport. If these assumptions are wrong, I will need to employ the emergency gear extension procedure, which may or may not result in lowered and locked gear. Finally, this plan assumes the cause of the emergency is that the alternator has failed, rather than the alternator failing as a symptom of another issue.

Deja Vu All Over Again

Less than a week later and flying a different airplane from the same flight school, I experienced another problem. It was during the checkride for my multi-engine instructor rating. The oral had gone well, the majority of the airwork was complete and we were at the point of demonstrating an engine shutdown and restart at altitude, a simulated engine failure on the runway and another shutdown at 800 feet agl. I shut down the right engine and secured it, checklist complete.

I then began the restart procedure. Hmmm…the unfeathering accumulator isn’t working; the prop is still feathered. Okay, we can use the starter to crank the engine…crank, crank, crank. Nothing. Getting any certificate or rating is an exercise in never giving up, and I worked on getting that engine restarted for 30 minutes, but no joy. Of course, halfway through the procedures the undervoltage warning light associated with the good engine became illuminated, signaling all was not well with the airplane’s electrical system. Are we having fun yet? The examiner and I resigned ourselves to the fact this was not going to work today. We were over an airport and land without further event, but we will have to finish the checkride another day.

Another day arrives. The weather isn’t great; however, it’s supposed to improve. The owner was supposed to have the airplane’s issues repaired by now, but nothing has been done and the local mechanic doesn’t want to help. I jump-start the airplane, the props come out of feather and all systems are “go.” I pick up my IFR clearance for the 30-minute flight to the examiner and launch.

Climbing through 1000 feet agl, the right alternator warning light illuminates. Then I notice the radio and transponder are flickering. The undervoltage light for the left engine is not illuminated. What’s happening? I’m now in solid IMC. The batteries are not charging. The electrical system is going dead. The electric HSI is wandering. This is not the typical complete-failure scenario pilots train for. This is far more dangerous: a partial failure. I let ATC know I have some problems. This is not at an emergency yet. However, I need to get on the ground.

But It Gets Better (Worse)

The controller tells me about a nearby airport reporting better visibility. Despite the electrical problems, I still have my Nav radios and receive vectors onto the ILS serving the airport I just departed. I also had my iPad and its EFB software. As ATC was giving me 10- and 20-degree course corrections, I was unnecessarily busy. It would have been better if I had simply been cleared to a fix and managed it on my own without all the relatively small heading changes.

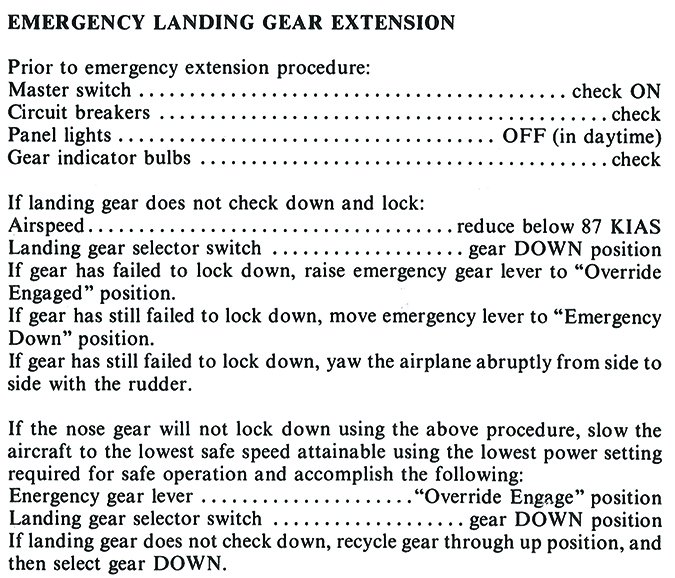

Soon I’m established on the ILS, the needles are alive and I’m cleared to land. I reach over and put the gear down at the final approach fix. And you know what happens next: Nothing. Nada. Zip. Bupkiss. This approach is not going to work out—I’m not going to continue it with the gear in an unknown state.

I tell ATC I’m going missed and start to work the problem. While navigating the miss and keeping the airplane more or less straight and level, I find the gear extension handle, read the checklist and follow instructions to manually lower the gear. This is the point at which, if I had power, I would verify three green lights. Nope, no green lights. Nothing. I did feel a pop…something down there has done something…what? How many? Has it locked? Couldn’t tell you. This is not my airplane; if I’m going to bend it, I want to make sure this isn’t my fault.

I call ATC, I explain my latest complication and request a vector to the nearby airport with good visibility, with the idea of getting someone on the ground to verify my landing gear is down and locked. While ATC works on that, I reassess my status. The batteries are weak. The gear is in an unknown configuration. And to add insult to injury, the fuel gauges are now reading in the red. Not yet empty, but my faith in this airplane has been shaken enough that I don’t trust that I have enough fuel left to do anything but land. I call ATC, requesting they roll the fire trucks. Perhaps if things go badly and I roll this up into a ball, someone can pull me out in time.

Nearing my divert field, I ask ATC to get me lower as I’m right at the base of the clouds. I can just about see the ground and the GPS shows me nearly at the airport. Then a hole opens up and I’m over the airport, runway in sight. I enter the pattern on a downwind. Left Base. Turn final. Check the flaps. No electricity; no flaps. Okay; I’ve trained for this, just add 10 knots to my normal approach speed. Soon enough, I discovered the gear was down and locked. The airplane was on the ground and I was safe.

Aftermath

The mechanic found one alternator belt was missing entirely and the other one was loose. It must have worked for a bit and then slipped, and then worked again, keeping up a pattern of working and slipping. The batteries were also found to be dry, leading to them not holding a charge properly.

In the end, I relied on my training, but not the part you may expect. It wasn’t the training on resolving simulated failures that helped me out; it was the training on how to use a checklist (see the sidebar above). And how to prioritize multiple issues, working through a problem. This is the training that helped me resolve the problems.

To the controllers who were with me through these emergencies, who I heard cheering in the background when I was safely on the ground, you have my eternal gratitude. Put up another save on the board.

In the real world, things generally don’t fail completely and abruptly. In fact, it’s hard to train for a real failure even as we instructors do our best to simulate them: We may cover an instrument, or retard the throttle, but we are limited in what we can simulate by the need to not create a true emergency while trying to simulate one. And the difference between fixing a known, actual failure using an already determined course of action with an instructor next to you is very different from groping around alone in an unfamiliar aircraft looking for the checklist, in IMC, as a failure of unknown origin sets off your panic responses.

Yes, I may have made some mistakes, including launching an airplane with unresolved issues. The most valuable lesson I can share is that most of these failures were partial ones and the choices I had to make were not black and white. For example, I had some electricity left, but not all I needed.

Emergencies are analog. They seldom present a clear, readily understood set of circumstances or solutions, and our required responses may not be as well-defined as the checklist or the instruction we received imply. Successfully getting on the ground in one piece always resolves the problem.

James Warmkessel holds FAA flight, instrument and multi-engine instructor certificates, and is an A&P. He’s also an aviation podcaster and IT professional living in the San Francisco area. Follow his podcast at AvStry.com.

thanks for info.