By Joseph E. (Jeb) Burnside

Owning an airplane can be a real pain. There are costs for insurance, tiedown/hangaring, annual inspections and debt service, all of which are incurred before the engine even turns over. Add in the hourly costs of fuel, oil, tires, unscheduled maintenance and overhaul reserves, and its a wonder anyone even wants to own their own airplane, much less fly it.

Then theres the paperwork and other responsibilities that come along for the ride. It starts with making sure the FAA has correct documentation of the crafts ownership, that all the required documents are both in order and aboard the airplane, and making sure that other various requirements cropping up from time to time-like Airworthiness Directives-either do not apply or are properly complied with. Then, owners are often forced to spend hours poring over logbooks and other documentation to ensure all required inspections are conducted and properly documented. Any modifications or repairs must also be recorded. All of this can generate mountains of paperwork, especially for older aircraft.

The more detail-oriented owners and operators among us come up with inventive ways to catalog and maintain all this documentation, including three-ring binders and multiple copies kept in fire-proof lockboxes. Some produce CD-ROMs of all records and maintenance manuals and carry them in the airplane.

While these paperwork requirements can often seem burdensome-and, when compared to automobiles, they are-there are reasons we track all of this information. One owner learned this the hard way on a cold night in January 2004.

Background

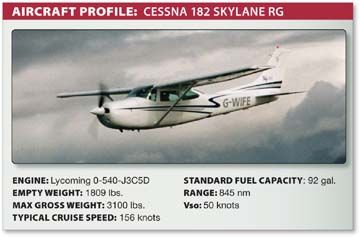

On January 5, 2004, at approximately 1825 Central time, a Cessna 182RG was substantially damaged during a forced landing following a loss of engine power near El Dorado, Ark. It was owned and flown by a non-Instrument-rated Private pilot who was seriously injured in the crash. His lone passenger was fatally injured.Night visual conditions prevailed for the cross-country flight originating from the South Arkansas Regional Airport at Goodwin Field (ELD) near El Dorado, Ark., at approximately 1815, and destined for the Memphis International Airport (MEM), Memphis, Tenn.

Shortly after takeoff, while in cruise flight at 3000 feet msl approximately 19 miles from the departure airport, the pilot heard a very loud bang, followed by another loud bang. While he was looking for a place to land, the engine seized up. He saw sparks from the engine, and smoke had filled the cabin area.

The pilot attempted to return to ELD, but the engine had lost all power and he initiated a forced landing to a field with the Cessnas landing gear retracted. Cockpit doors were partially opened to ventilate the smoke. The airplane collided with unseen trees and a steel fence during the ensuing crash landing.

Investigation

Maintenance records indicated that the airplanes Textron-Lycoming O-540-J3C5D engine was overhauled by a factory authorized repair station to manufacturers new part limits, including all applicable airworthiness directives, on April 25, 2000. At the time of the accident, records indicated the engine had accumulated 438.6 hours SMOH.

Since overhaul and installation on the airplane, a series of service bulletins were issued on the engine noting reports that operation at high temperatures can cause the converter plate gasket on the oil filter base to become extruded from its seat, allowing oil to leak out between the plate and the accessory housing. Subsequently, Emergency Airworthiness Directive (AD) 2000-18-53 was issued addressing this same problem. The AD stated, engines with more than 50 hours time since new (TSN), time since overhaul (TSO), or time since last replacement of the oil filter converter plate or gasket must have the gasket replaced before further flight to prevent complete loss of engine oil and subsequent seizing of the engine, and possibility of fire.

The NTSB could not find any logbook entries noting compliance with the various service bulletins or the AD. The engine overhaul work order revealed the affected oil filter converter plate gasket was installed at the time of engine overhaul.

At the accident scene, the enggine crankcase had two holes in the top half of the crankcase. The rear accessory housing and components were wet with fresh oil.

Teardown of the engine revealed the oil filter converter plate gasket was extruded in multiple locations. The oil filter element, oil suction screen, and oil sump contained metal debris. Two of the main crankshaft bearings displayed signs of severe heat distress, as did several connecting rod journals. Four of the engines six connecting rods were separated.

Probable Cause

The National Transportation Safety Board determined the probable cause(s) of this accident to include the loss of engine power as a result of loss of engine oil due to the failure of the oil filter converter plate gasket and the noncompliance to an airworthiness directive. Contributing factors were the lack of suitable terrain for the forced landing and the dark night lighting conditions.

In addition to being legal requirements for continued airworthiness, ADs and a manufacturers service bulletins are designed to highlight a deficiency in an airframe, engine or appliance that demands attention to ensure safe flight. Of course, great controversy often surrounds a proposed AD-whether for reasons of cost, impracticality, perceived benefit or other reasons. Owners of specific aircraft types, in fact, have grouped together from time to time in well-financed efforts to modify or defeat proposed ADs they dont consider appropriate or cost-effective. This is as it should be.

But many other ADs are fairly simple affairs, mandating simple replacement of one small part or another. In this instance, an AD requiring replacement of an oil filter gasket we found online for under $25 seems like a no-brainer. Especially if its designed to prevent all of the engines oil from going overboard.

This winter might be a good time to sit down in front of a roaring fire and go through all your logbooks to make sure everything that should be done has been done. Thats something we strongly support, especially on a cold January night.

Also With This Article

“Engine Monitors: Predicting Trouble”