While conducting flight reviews and stage checks for students working toward various airman certificates, I’m finding pilots who do not have a strong understanding of the operation and limitations of light aircraft braking systems. I’ve also noticed many pilots misuse the brakes in landing and taxiing. For the former, brakes are incorrectly and/or unnecessarily applied immediately following landing. For the latter, excessive engine power requires the pilot to “ride the brakes” to control the airplane. Both are examples of poor technique.

As we’ll see, misusing brakes during all ground operations, not just landing and taxiing, can be hazardous. As a brake overheats, it can fail, causing the pilot to lose control of the aircraft. In extreme cases, abused brakes can catch fire. There’s a better way.

Brake Systems 101

The size, weight and landing speed of an airplane greatly influence the design and complexity of its brake system. An original Aeronca 7AC Champion, for example, might use a variation on drum brakes. For most Champs—light, inexpensive and relatively low-powered airplanes—they’re perfectly adequate. Typically, a general aviation airplane will employ a single disc or rotor on each main wheel, as depicted on the Piper Navajo left main wheel and brake pictured above. Heavier, faster airplanes likely employ a dual-disc system, and large jet transports can require a set of brakes weighing more than the Champ.

Brakes for both main wheels are operated individually by pushing on the top of the floor-mounted rudder pedals at both pilot stations. Equal pressure applied by the toes to the top sections of both left and right pedals actuate the brakes and slow or stop the airplane in a (hopefully) straight line.

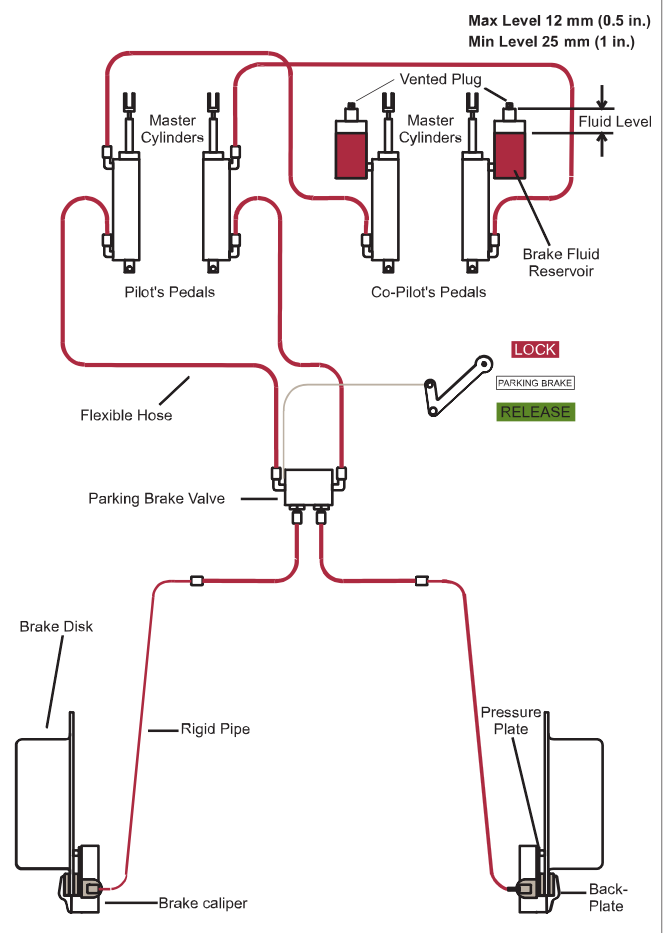

For many airplanes, a master cylinder for each main wheel brake is mechanically connected to the corresponding rudder pedal (i.e., right main brake to the right rudder pedal, left main brake to the left rudder pedal). When the pedal is depressed, a piston inside a sealed fluid-filled chamber in the master cylinder forces hydraulic fluid through a line to the piston(s) in the brake assembly. A disc brake uses calipers to squeeze pairs of pads/linings against a disc/rotor to create friction when the brakes are applied. This action retards the rotation of an individual wheel, either to reduce rotational speed or to hold both main wheels stationary.

When pressure is released, a spring in the master cylinder retracts its piston, pressure is released and the pads/linings are retracted, allowing the wheel to turn freely. Not all airplanes have toe brakes. Some—like the Champ—use heel-activated brake pedals mounted near each of the rudder pedals. A mechanism often is used to maintain hydraulic pressure and keep the brakes applied when the airplane is parked.

Brake system malfunction or failure may be signaled by gradual decrease in effectiveness following brake application, also referred to as brake fade. It’s a reduction in stopping power that can occur after repeated or sustained application of the brakes. Noisy or dragging brakes, soft or spongy pedals, excessive pedal travel and weak braking action are all characteristics of brake malfunction. Should any of these conditions be encountered, the airplane should not be flown and the problem reported immediately to maintenance. Attempting to taxi and land with a known brake deficiency is an accident waiting to happen.

Parking Brake

In my experience, many pilots incorrectly believe by simply pulling the parking brake knob, the brakes will become activated, as for a car. For many airplanes, setting the parking brake is a two-step process. A Cirrus SR22, for example, requires the pilot to first apply the brakes with the rudder pedals. Next, while holding pressure on the pedals, pull the parking brake knob; this allows a valve in the system to close, trapping pressure in the system and locking the brakes.

The effectiveness of your airplane’s parking brake depends on that valve, a relatively inexpensive item that can develop leaks over time. So it’s never a good idea to depend on a parking brake alone to keep an airplane motionless, even on a flat ramp. Chock it instead.

And since most FBOs will want to tow the airplane to a different location once you’ve parked and secured it, engaging the parking brake on a transient ramp is rarely a good idea. If towing is attempted with the parking brake engaged, real damage can occur to towing pins and landing gear, as well as tires. Since parking brakes mostly fail gradually, not all at once, airplanes have been towed with the parking brake partially engaged, heating up the brakes, wearing down the brake pads/linings and causing unnecessary tire wear. Check that the parking brake is off and chock it instead.

Differential Braking

Brakes don’t always have to be applied equally and at the same time. Applying them independently can assist in steering an airplane on a crowded ramp or down a taxiway. For airplanes with a steerable nose wheel (e.g., Cessna 172, Cirrus, Bonanza, etc.), the correct procedure is to apply pressure to the bottom of the rudder pedal in the direction of the intended turn, while using just enough power to taxi the airplane no faster than a brisk walk. Brake pedal pressure should only be applied sparingly to assist in turning the airplane.

For airplanes with a non-steerable, castering nosewheel (e.g., Cirrus), minimal differential pressure should be applied with the toes to assist in turning the airplane while using minimum power (500 to 800 rpm). Ideally, the pilot should release the brakes to allow the airplane to roll forward a bit and ensure the nosewheel is centered before applying a brake in the direction of the desired turn. To “ride the brakes” and use higher power settings while taxiing is always inappropriate. Doing so needlessly erodes brake linings and may lead to overheating the brakes, brake failure and a fire.

Brakes And Heat

A fundamental principle of brake operation involves the conservation of energy principle, which states energy is neither created nor destroyed, but can only be converted from one form to another. The airplane’s kinetic energy is converted into heat energy when brakes are applied. Heat generated by the brakes is proportional to the amount of kinetic energy being converted. Because kinetic energy equals one-half of the mass multiplied by the square of the speed (Energy = Weight * Speed2), the energy the brakes must convert to heat is doubled by doubling an airplane’s weight and quadrupled by doubling its speed. Brake heat energy is only related to the amount of kinetic energy being converted: It doesn’t matter if the brakes are applied hard for a short time or lightly for a long time—the resulting heat will be the same if the desired speed reduction is the same.

Brake system heat is dissipated three ways: radiation, conduction and convection due to a temperature gradient. Radiation is the transfer of heat through space. Conduction is the transfer of heat to parts of the brake system and other attached aircraft parts. Convection is the transfer of heat from the brake to the air moving across the brake. All things being equal, the larger a brake rotor, the better it will be at dissipating heat.

Brakes For Landing

As the FAA’sAirplane Flying Handbook(AFH, FAA-H-8083-3B) tells us, to obtain optimum braking performance, put maximum weight on the main wheels after touchdown by applying back pressure to the flight controls without lifting the nosewheel off the runway. This is referred to as aerodynamic braking. The raised elevator causes a negative aerodynamic load on the tail, which has the effect of increasing the airplane’s weight and, therefore, braking effectiveness.

When sufficient runway is available following a normal landing and with power set to idle, the airplane should be allowed to decelerate before applying brakes. When needed, brake pressure should be applied judiciously at a distance down the runway just prior to turning onto a taxiway. This saves wear and tear on the brake linings and tires.

If runway length and/or airplane speed is a concern, careful application of the brakes should be initiated only after the nosewheel is on the ground and directional control is established. Maximum deceleration following landing is not achieved by “slamming on the brakes,” which can causes the wheels to lock and skid, perhaps placing the airplane out of control. One method is to apply just enough brake pedal pressure to induce skidding and then back off slightly on the pressure. Maximum braking effectiveness occurs when sufficient brake pedal pressure is applied to almost stop wheel rotation. As stated in the AFH, braking effectiveness is not improved by alternately applying, releasing and reapplying brake pressure. During the landing roll, directional control may be managed by carefully applying differential braking while exercising caution to avoid over-controlling.

Toes, Touchdown And Tires

By inappropriately pushing on the brake sections of rudder pedals at the moment of touchdown, the main tires can be locked in place. On contact with the runway, a section of tread on one or both main tires can be worn away, flat-spotting the tire or, in extreme cases, wearing into the tire’s casing. Prior to landing, pilots should ensure their toes are positioned on the bottoms of the rudder pedals (see the sidebar above) and ensure the parking brake knob is not engaged.

Depending on how they’re used, an airplane’s brakes can help or harm. Misusing them can result in ruined tires, loss of control and fires. Meanwhile, keep your taxi speed down and use the brakes sparingly, and they’ll likely be available when you really need them. In any case, the brakes on a personal airplane are nowhere near as powerful or robust as the brakes on a modern car or truck. They’re usually much smaller, even though they often have to do the same work. Plan ahead.

The Curse Of The Castering Nosewheel

To save weight and complexity, manufacturers sometimes design their airplanes without nosewheel steering, allowing it to caster instead and forcing pilots to control the airplane’s direction on the ground with differential braking. Castering, unsteered nosewheels can be found on many airplanes, including the line of Grumman singles and the Cirrus SR20/22. The only real problem with a castering nosewheel is when we want to taxi fast.

In that situation, pilots can find themselves using moderate-to-high engine power to taxi while holding pressure on a brake to help keep the airplane headed in the right direction. As images at right attest, when brakes get hot, they can catch fire.

In 2005, the FAA issued Special Airworthiness Information Bulletin SAIB CE-05-77, which reprinted a Cirrus service advisory and noted, “The most common cause of brake failure is the creation of excessive heat through improper braking practices.Riding brakes while taxiing is similar to driving with one foot on the brake and one foot on the gas. This causes a continuous buildup of energy that would otherwise be moving the airplane” (emphasis in original).

In 2006, an airworthiness directive was issued, calling for new brake caliper piston O-ring seals, a revised POH and, for some airplanes, modifying the main wheel fairings to facilitate inspection and prevent brake fluid retention. Since then, the number of Cirrus brake fires has been reduced, but they still occur.

Preflighting Your Brakes

Your preflight inspection is the preferred time and place to discover problems with your brakes. At right is a typical brake system, manufactured by Cleveland and installed on a Beech Bonanza. Identified components include:

1—The brake disc, which should be free of cracks, dirt, extreme heat signatures (discoloring) and corrosion.

2—The brake lines can be either a rubber hose and/or metal tubing. Look for cracks/corrosion in metal tubing and worn or frayed rubber lines.

3—The brake caliper, which should be securely attached to its mounting plate, with no loose fasteners or cracks. The brake pads (not shown) are held in place next to the disc by the caliper and should show at least1/8of an inch of material.

4—The fitting at the bottom of this caliper is the brake fluid bleed screw, a likely place from which fluid can leak. Check underneath it for red fluid.

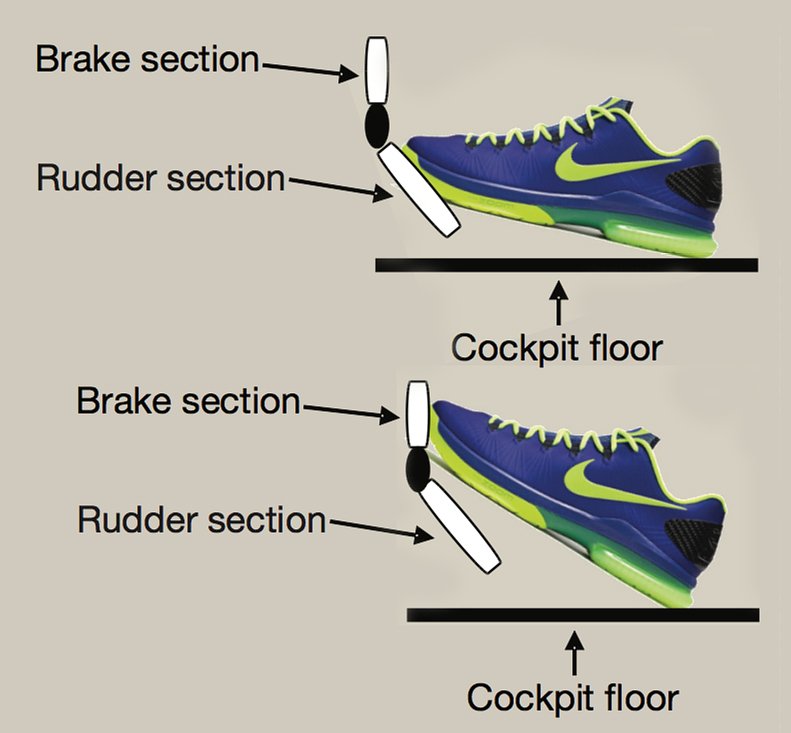

Do You Know Where Your Feet Are?

On one level, it’s sad we need to point out where your feet should be when landing, but landing with the brakes applied is a thing. Depending on the runway and crosswind conditions, landing with brakes applied easily can lead to losing control on the runway after touchdown. It always increases wear and tear on the brakes, tires and landing gear. And it’s always poor technique.

Pilots land with brakes applied most often when performing a short-field landing. In anticipation of needing to stop the airplane as soon as they can, they position their feet so they won’t need to move them from the rudder position to the brakes after touching down. Consciously or not, they will add pressure to the brake master cylinder, which at least partially applies the brake before touchdown.

A better technique is to ensure your feet are off the brake portion of the rudder pedal when landing. The top image at right depicts proper foot placement when only the rudder and/or nosewheel steering is to be used. The bottom right image depicts foot placement when we’re trying to use the brakes.

Mike Banner is a flight instructor at University Air Center, Gainesville Regional Airport (GNV), Gainesville FL, professor at the University of Florida in Gainesville, and instructor and mission pilot in the U.S. Air Force Auxiliary/Civil Air Patrol. A CFII-MEI, he has 5,000 hours of flight time and owns a GCBC Citabria.

Good article and good reminder about brakes.

“As the FAA’sAirplane Flying Handbook(AFH, FAA-H-8083-3B) tells us, to obtain optimum braking performance, put maximum weight on the main wheels after touchdown by applying back pressure to the flight controls without lifting the nosewheel off the runway. This is referred to as aerodynamic braking.”

A minor point, but the above technique is not “aerodynamic braking,” and the AFH does not say that, exactly. Aerodynamic braking occurs when you keep the nose wheel off the ground without lifting the main wheels off the ground. The high AOA results in high aerodynamic drag (braking). Not as effective as mechanical braking, but less wear on the brakes.