From the beginning of our primary training, we learn how to check our airplane’s fuel quantity and quality, and how to position various controls to ensure the engine starts and stays running. We know we can turn the fuel off and on, and perhaps select from which tank the engine will draw, but what happens after that often is a mystery. What’s going on between the fuel selector valve and the engine?

The quick answer is one of two things: The fuel either flows into a carburetor where it mixes with air and then is routed to each cylinder, or it moves through a more-complicated fuel injection system before getting to the cylinders. The air arrives separately. Both systems meter fuel and air to the engine, are reliable and work well. But they each have their quirks, and knowing how they work and can fail is critical to a full understanding of the airplane’s systems.

Comparisons

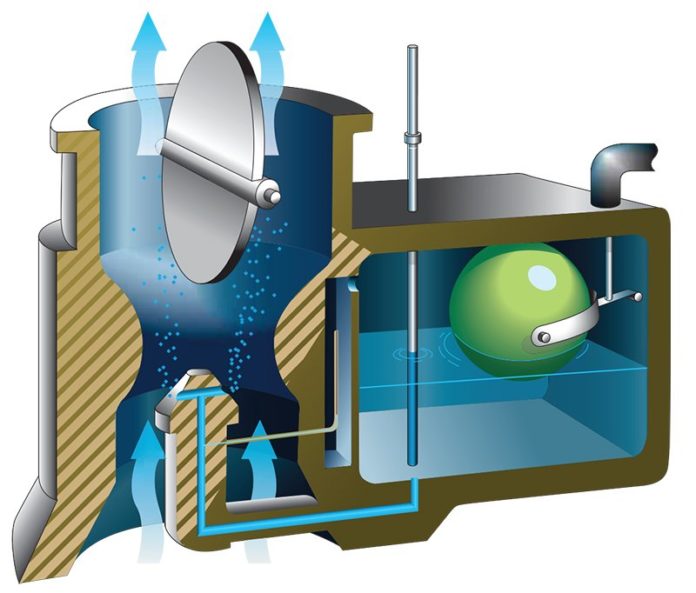

Thanks to tight emission controls and the never-ending quest for better mileage, the carburetor has largely left the automotive market but remains in widespread use on piston aircraft engines. A carb is relatively simple, light and easy to maintain, and it’s inexpensive. It depends on the venturi effect to vaporize fuel and mix it with air. Through an engine’s intake system, that combustible mixture then flows to the cylinders where, if everything is working as it should, it’s ignited by the spark plugs, burns and produces power.

But it’s not as efficient as fuel injection at distributing a combustible mixture to the cylinders. Often, the same basic engine will produce greater power when a fuel injection system is fitted instead of a carburetor. As an example, consider the Lycoming O-540 engine found in Piper Comanche 250 models. It’s carbureted and is rated at 250 hp, hence the airplane model’s name. Meanwhile, take the same basic engine and replace the carb with a fuel injection system. It now produces 260 hp, as used in the Comanche 260. Similar examples of increased power output exist elsewhere in Lycoming’s product line as well as in Continental’s.

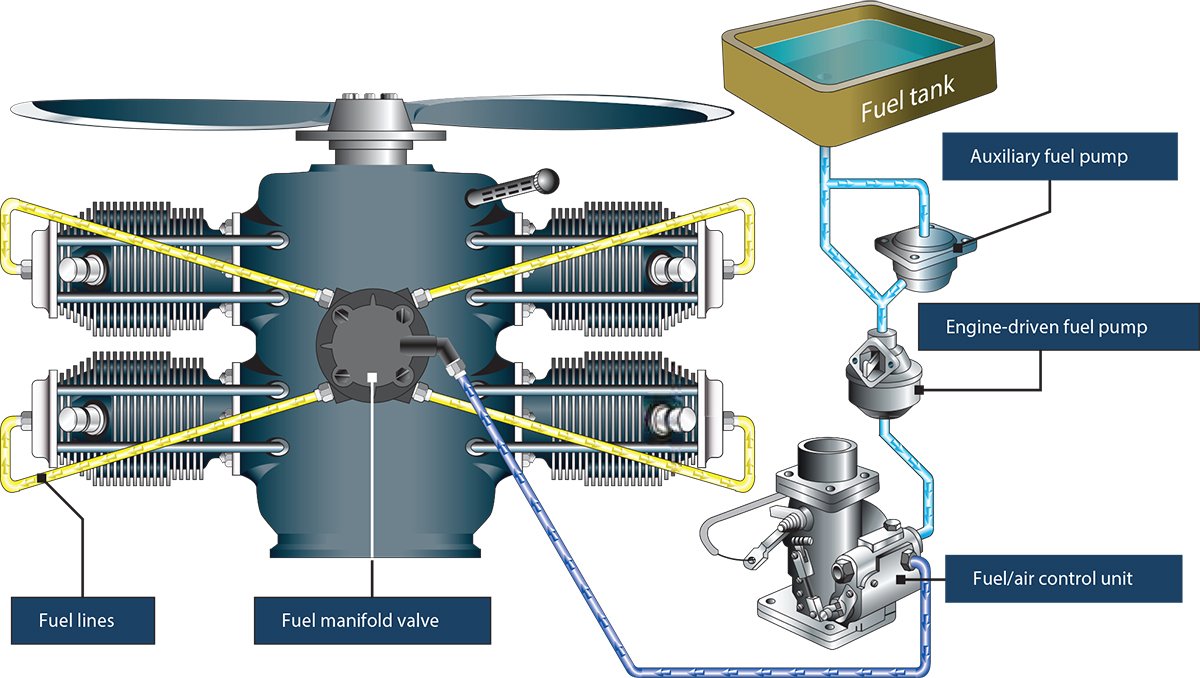

But there’s no free lunch. A fuel-injection system uses an engine-driven pump to push fuel through a metering system, which then flows through an injector line to each cylinder. A backup electrical pump often is required, which means additional weight, current draw and associated wiring. A cockpit-mounted gauge monitors fuel pressure and presents the results in terms of flow to the engine. And a pilot suffering failure of the engine-driven pump must know to activate the electric one to restore power. The diagram at right identifies the various components of a fuel-injected engine.

An engine with fuel injection to each cylinder also must have a way to distribute air, since the injector lines carry only fuel. The required induction systems also exist on a carbureted engine. Some engines may benefit from installing balanced fuel injectors, which compensate for differences in airflow to the various cylinders. Fuel injection systems are more complicated than carburetors, and they can be expensive to maintain, replace or overhaul. But they generally allow greater power than a same-displacement carbureted engine.

Icing

Another major difference between carburetors and fuel injection systems is their susceptibility to icing. Carbs are famously prone to creating ice internally, blocking the fuel/air mixture’s flow. Sudden, unwanted quiet has greeted pilots who forgot about or misused the carb heat control. Some engine/airframe combinations are more prone to carb icing, and others require carburetor heat to be applied below a specified rpm while the same basic engine in another airframe has no such limitation.

Fuel injected engines, meanwhile, are largely immune to carb icing since there’s no carburetor (or a venturi to help atomize fuel, which is a source of the carb icing problem). They can, however, still be blocked by ice, which can form at the air intake, usually on the front of the engine cowling. An alternate air door is provided to bypass a blocked air intake, but it can require pilot activation. Induction icing affecting a fuel-injected engine usually only forms when the airplane is operated in conditions conducive to airframe icing, a completely different situation. Induction icing also can block the air intake to a carburetor.

Priming And Hot Starts

A carbureted engine usually has a manual priming system to pump raw fuel to one or more cylinders, making cold starts easier. The electrically powered auxiliary fuel pump on a fuel-injected engine can pull double duty as part of a priming system: Momentarily push a button or flick a switch and the pump primes all cylinders for you. Starting a fuel-injected engine may involve an additional step or two, usually involving the priming process and correct position of the throttle and mixture controls.

One major downside for some operators is the fuel-injected engine’s hot-start characteristics. Park an airplane after a flight and the engine cowling no longer has cooling air flowing through it. Residual heat can build up under the cowling, vaporizing fuel in the injector lines and preventing it from reaching the cylinders in sufficient quantity to start.

A manufacturer may specify a hot-start procedure. When it doesn’t, pilots may be forced to experiment to find the right fuel/air mixture. Poor technique has been known to result in engine fires as too much fuel is used for priming, or in a dead battery as a pilot tries and fails to conduct a hot start. Carbureted engines usually don’t suffer from hot-start problems.

At the end of the day, carburetors and fuel-injection systems perform the same tasks, just differently.