Each month in the back of this magazine, we chronicle recent accidents we hope are of interest to readers. A glance at a random month’s entries likely would reveal that a substantial portion of them involve total or partial failure of a piston single’s engine. Yes, there’s selection bias involved—we typically try to highlight the most educational accidents and incidents, and many in-flight engine failures don’t result in an event reportable to the NTSB.

But the evidence also points out that pilots frequently mishandle the event, perhaps just as they mishandled their fuel management, since many engine-failures can be traced to fuel starvation or exhaustion. To be sure, mechanical failures that are no fault of the pilot also can fail an engine. Regardless of the reasons, once the engine quits, it’s the pilot’s job to manage the airplane’s remaining energy and come to a safe stop. There are some considerations beyond just flying the airplane, but let’s talk about that first, if only to get it out of the way.

THE BASICS

We’ve all been trained in the engine-out glide. Typically, the instructor will have a field or even a nearby runway in mind as a destination when power is reduced, while the pilot focuses on maintaining airspeed and forgets to look around, especially out the other side of the airplane or even behind it. We all get a good laugh out of the pilot’s failure to find the best landing area, but there’s a lesson there, too, which is to not get fixated.

Early in the exercise, after we’ve performed all the remedial actions designed to restart the engine, it’s time to configure the airplane. It’s a rare engine-out checklist that advises extending flaps until a landing is assured, so unless the failure comes right after a flap-extended takeoff and they are the only thing keeping you in the air, they should remain stowed.

Same for retractable landing gear, on both counts. If the gear is extended when the engine quits, and time and altitude allow, retracting it definitely will eliminate drag over the long run, but there may be a temporary increase in drag as the gear cycles. No bueno at low altitude. In the case of a failure just after liftoff, leaving the gear down to absorb energy likely is a better tradeoff than retracting it. Cowl flaps, if any, and other drag-producing equipment—an air conditioning condenser, maybe; spoilers/speed brakes certainly—also should be closed/retracted.

The recent and ongoing revolution in portable computers and their aviation-specific applications has produced some worthwhile tools for managing the engine-out glide and even to help us avoid being out of gliding range to an airport.

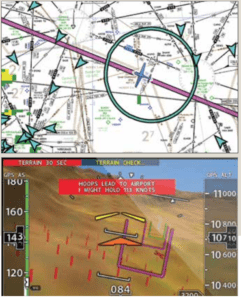

As one example, the popular EFB app ForeFlight includes Glide Advisor™, a feature the company says uses “terrain, GPS data, winds aloft, and your aircraft’s best glide speed and ratio [to shape] a glide range ring around your ownship icon on the moving map display.” An example is shown at top right. By referencing the glide range ring in real time, a pilot can maneuver to never be out of gliding distance to land, for example, or choose a less-risky altitude.

At bottom right is a promotional image from Xavion, a situation-awareness enhancement app its publisher says “constantly imagines engine-failed glides to every runway in gliding range, and then shows you the safest-possible route as a Highway-In-The-Sky to take to an airport in the event of engine failure.”

WHAT SPEED TO FLY?

While all this is going on, you also need to obtain and maintain an optimal airspeed. There are two possibilities: best glide speed, VBG, and best lift over drag speed, sometimes called minimum sink speed, and typically abbreviated to VLD. The former provides the greatest glide distance; the latter is for when you don’t care about glide distance but want/need more time aloft, as when soaring the mountain ridges in your Cirrus.

For typical light airplanes, manufacturers publish a single airspeed to fly in an engine-out glide. Some come with more than one number: Cessna publishes three speeds for the 172S Skyhawk SP: 70 KIAS for engine failure immediately after takeoff, 68 KIAS (labeled “best glide speed”) at other times and 65 KIAS when 10 or more degrees of wing flaps are deployed, as when landing without engine power. If no best glide speed is published for your airplane, it can be approximated by flying at the midpoint between best rate of climb speed (VY) and best angle of climb (VX).

These values typically are for maximum gross weights. In other words, unless the failure occurs on takeoff, true best glide speed will be obtained at some lower number. How much lower should that number be? The accepted rule of thumb is to reduce the published best glide speed by five percent for every 10 percent below maximum gross weight. As an example, my tip-tank-equipped Debonair grosses out at 3550 lbs. If it’s just me, full tanks and some gear, the airplane weighs about 3120 lbs. at takeoff. That’s a difference of 430 lbs., or slightly less than 13 percent. Half of 13 is 6.5; I should reduce my published best glide speed of 105 KIAS by 6.5 percent, or 6.8 knots. My weight-adjusted best glide speed in that scenario is 98 KIAS.

You can find these speeds on your own, of course. As the General Aviation Joint Steering Committee (GAJSC) wrote in a safety enhancement on the topic, “Start at VY or the manufacturer’s recommended best glide speed with power off…and note speed vs. sink rate as you adjust pitch to reduce airspeed. For the most useful results, you should do this as close to typical mission weight as possible. To identify minimum sink speed, look for the highest speed forward that will give you the lowest rate of descent.” (Disclosure: I worked with the GAJSC to help develop this and other powerplant failure-related safety enhancements.)

Finally, we should note that VBG and VLD occur at specific angles of attack. If you have an angle of attack indicator, use it. If not, fly at the appropriate airspeed.

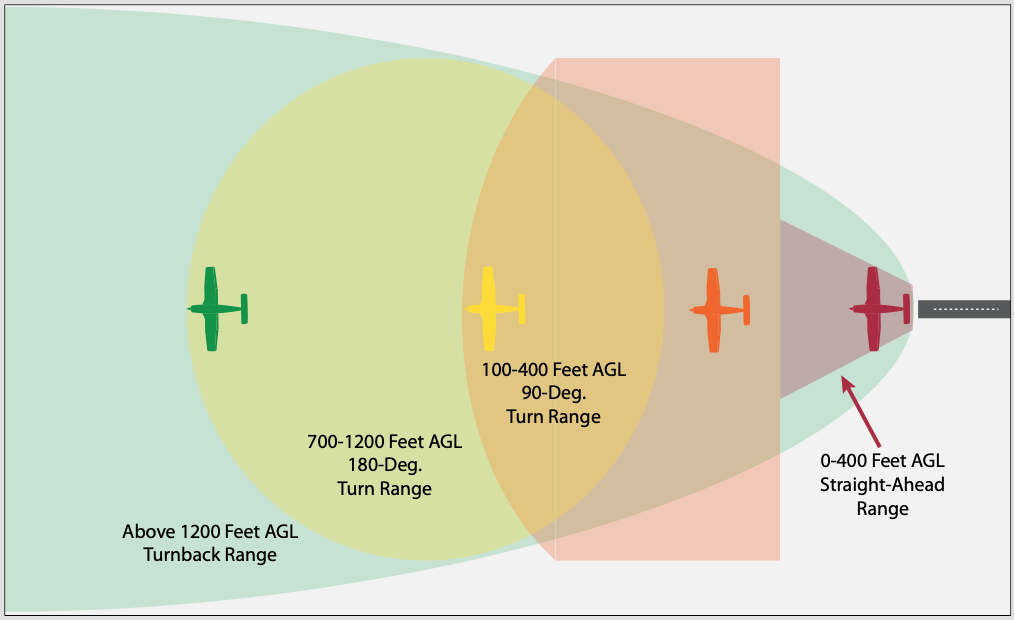

Landing straight ahead or turning back to the departure runway are not the only options when the engine fails shortly after takeoff. Instead, consider establishing altitude and/or distance zones within which your response to an engine failure is predetermined. Here’s what we mean, adapted and condensed from Tom Turner’s October 2019 Aviation Safety article, “All Or Nothing?”

Straight-Ahead Zone

Until the airplane reaches at least 400 feet agl, your only real option in the event of engine failure is to land almost straight ahead. You probably have less than a minute to prepare to touch down, less if you turn and create a horizontal lift component. Why 400 feet? This is the lowest altitude at which IFR flights are expected to make a turn when departing and is one we should be briefing anyway.

90-degree Zone

Between 400 feet agl and about 700 feet, you may be able to turn as much as 90 degrees left or right to align with the best landing option. To survive this, you need to know ahead of time what that option will be. Google Earth or another resource can help you make this decision before takeoff.

180-degree zone

Between 700 feet agl and about 1200 feet, you are in the range where you may be able to turn up to 180 degrees to align with the best landing option. This may not put you back on the runway, but it might get you to level airport property.

Runway Zone

Above 1200 feet agl, you should have enough altitude to actually get back to the runway behind you if you do everything right. But you likely won’t know this unless you practice and make careful notes about climb performance, distance from the airport and turning rates. Regardless of the range and the options you attempt, when you glide back through 400 feet agl, you’re likely less than a minute from touching down. Level the wings and land on the best option that’s roughly straight ahead, to help prevent a cartwheeling arrival that’s sure to do more damage to the airplane and its occupants than the straight-ahead alternative.

SHORTLY AFTER TAKEOFF

The worst-case scenario for an engine failure is right after takeoff. The airplane is relatively slow—perhaps below its best glide speed—and the immediate challenge is to get the nose down far enough to maintain that target speed. That can require a hefty push on the pitch control to establish the correct attitude without nibbling at a stall. Meanwhile, and thanks in part to related articles and a video by AOPA, plus a couple of recent accidents, there’s been an uptick of interest among some pilots, especially those hanging out in online forums, in turning back to the departure runway when the engine fails shortly after takeoff. It’s a natural desire to want to be back on the closest runway, but turning back—sometimes known as the impossible turn—can be the worst bad choice you have.

Our January 2007 issue featured a detailed article by spinmeister Rich Stowell, “Turnbacks Reconsidered,” in which he wrote about the results of simulator-based tests flown by several pilots, ranging from 40-hour students to those with more than 200 hours. The simulator emulated the characteristics of a light, single-engine airplane with fixed landing gear and a fixed-pitch propeller.

According to Stowell, “a ‘successful outcome’ was defined as follows: In all cases, the maximum rate of descent could not exceed 2500 fpm, rate of descent at touchdown could not exceed 500 fpm, and bank angle had to be within five degrees of wings-level below 100 feet agl. For turnbacks, the airplane had to complete at least 175 degrees of heading change without exceeding a 55 degrees of bank.

“One hundred percent of the attempts to proceed straight ahead (35/35) resulted in successful outcomes—pilots maintained control of the airplane all the way down to the ground every time. The probability of survival in an actual emergency: high….”

“By contrast, only 62 percent of all of the attempted turnbacks were successful (69/112). Thus, nearly two out of every five attempts failed. And the majority of failed turnarounds culminated in stall/spin departures [from controlled flight]. The probability of survival from the failed turnbacks: low. The probability of significant crash damage to the airplane: high.”

A host of other factors are part of the equation. For one, the longer the runway, the more likely may be a successful outcome if the airplane doesn’t have to glide as far to reach pavement. Another is the wind, since a stiff one will reduce groundspeed on initial climb, keeping the about-to-be-powerless airplane closer to the runway. When pointed back to the airport, that same breeze may provide a tailwind. Climb rate, wing loading, total drag, how quickly the reversing turn is made and how far the airplane is from the runway when the engine fails all factor in to whether a turnback maneuver will be successful.

In our January 2014 issue, Catherine Cavagnaro wrote about her test flights to determine if stopping a fixed-pitch propeller increases glide performance by minimizing the drag of a windmilling prop. Her research revealed an average 8.3 percent improvement in glide performance, the time it took to glide from 8000 feet msl to 7200 feet at the airplane’s published best-glide speed. Speaking to the pilot whose engine with a fixed-pitch prop has failed, she wrote, “Should he or she decelerate below published VBG to stop the propeller and extend the glide? Possibly, recognizing that the benefit can be approximately eight percent greater glide distance, and that may put more suitable terrain in reach.”

However, it’s important to note these tests were performed under ideal, consistent conditions and no attempt was made to determine if the time spent at airspeeds slow enough to stop the prop affected the overall glide distance. The value of stopping the prop depends on a host of variables, but it can be worthwhile. Testing with your airplane will tell the tale.

For those flying singles with a constant-speed propeller, there’s an easy way to approximate these results: pull the prop control all the way back to its low-rpm/high-pitch setting when the engine fails and can’t be revived. You should be able to sense the acceleration. Caveats include that the prop may not respond after a failure in which engine oil goes overboard, since that’s the working fluid in the propeller hub. Also, don’t forget to return the prop control to a more appropriate setting before adding power after a simulated engine-out exercise.

PRACTICE

Practicing engine-out glides can be dull and boring, but we can spice it up. Typically, the exercise starts at a healthy altitude and, after running the checklists and configuring the airplane, you descend until it’s obvious whether the chosen landing area could have been reached if the engine actually had failed. While engine-out glides certainly may be practiced solo, it helps to have an instructor along, or a safely pilot, to provide a critique and ensure you don’t forget something.

That’s especially true if you want to go out and do some testing to find the best glide and minimum sink airspeeds for your airplane at different weights, which we recommend. And we strongly recommend having an instructor along if you’re out practicing turnbacks. Of course, you’ll pick a quiet field for turnback practice, not a busy one where you can be head-on with departing traffic.

If you go out to practice turnbacks and/or engine-out glides, be sure to keep it realistic and account for the “startle factor” by waiting five seconds before reacting to the engine “failure.”

Jeb Burnside is this magazine’s editor-in-chief. He’s an airline transport pilot who owns a Beechcraft Debonair, plus the expensive half of an Aeronca 7CCM Champ.