Annual inspections are often a sore subject for both the aircraft owner and the shop. There have been and will continue to be misconceptions as to what an annual is and what it is not. Our first order of business is to note the requirement for an annual inspection comes from FAR 91.409, requiring an inspection by an authorized individual within the past 12 calendar months for the aircraft to be legally operated. The annual inspection scope and detail is spelled out in FAR 43’s Appendix D. The objective is to determine that an aircraft conforms to its type certificate or properly altered condition and is in a condition for safe operation, and therefore airworthy.

Aircraft not requiring an annual inspection are those carrying a special flight permit, a current experimental certificate, and a light-sport or provisional airworthiness certificate. With the exception of the special flight permit, these aircraft will require some type of equivalent inspection. For experimental, amateur-built aircraft, a “condition inspection” with at least the scope and detail listed in FAR 43 Appendix D is required annually.

Alternatives

An option to the annual inspection is a progressive inspection program, which can help minimize maintenance downtime. Progressive inspections benefit operators and owners whose aircraft experience high utilization, like FBOs, flight schools and corporate flight departments.

Unlike an annual or 100-hour inspection, a progressive inspection allows for more frequent but shorter inspection phases, as long as all items required for the annual and/or 100-hour inspection are accomplished within the required time frame. A progressive maintenance program must be FAA-approved and is not transferable. Most private (for pleasure) operators choose the annual inspection routine as a less troublesome option; however, no matter which option is chosen, the entire aircraft must be inspected once every 12-month period.

Pre-Inspection Preparation

One secret to obtaining a good inspection depends a lot on the preparation that is done prior to the actual inspection. The aircraft owner is responsible for proper maintenance records, and having up-to-date records available to the inspector is essential. Incomplete records can cause multiple problems, potentially impacting not only the cost of the annual but, more importantly, safety.

Necessary records include logbooks, current registration, copies of FAA Forms 337, instructions for continued airworthiness, weight and balance information, equipment listing, flight manual and airworthiness directive status. The inspector should have access to, and be familiar with, maintenance manuals and type certificate data not only for the airframe but the powerplant as well. It is very important that the inspector be familiar with these manuals and data for the specific make and model of aircraft.

Pre-Inspection Details

Check that the aircraft and engine data plates reflect the logbooks/maintenance records. Prior to the actual inspection, a review of the technical data is necessary—the most important check is of the type certificate data sheet (TCDS), as this document is specific to makes and models of not only the aircraft but also its powerplant. There are many models of Lycoming 0-320 engines, for example, that are similar, but it may not be approved for a specific model of aircraft.

A thorough review of the airworthiness directives (ADs) also is in order to verify compliance status. A worst-case example might be an AD requiring replacement of a crankshaft by a specified time or date has been exceeded: The aircraft/powerplant combination is not airworthy. Life-limited parts are other items that can affect airworthiness if the item is at or beyond the limit. The current equipment list is also important to review to ensure that only approved items are installed.

No two aircraft are the same, and they’ll have differing requirements. A written inspection plan should be used to keep the owner informed. The inspection itself is primarily a visual task. Minor disassembly—removing inspection covers, open cowlings and gain access to cabin-mounted components—may be required.

Owners may want to combine the annual with various others tasks, like changing engine oil or replacing a tire/tube. Again, such work isn’t part of the inspection, but these tasks fall into the preventive maintenance portion of FAR 43’s Appendix A and can be performed by a certificated pilot.

Corrective action requires that defective parts must be replaced with new parts or repaired in accordance with the latest approved revision of AC 43.13, Acceptable Methods, Techniques, and Practices – Aircraft Inspection and Repair. Reassembly requires lubrication of the slip joints with a high-temperature anti-seize compound complying with the MIL-A-907E specification or its equivalent.

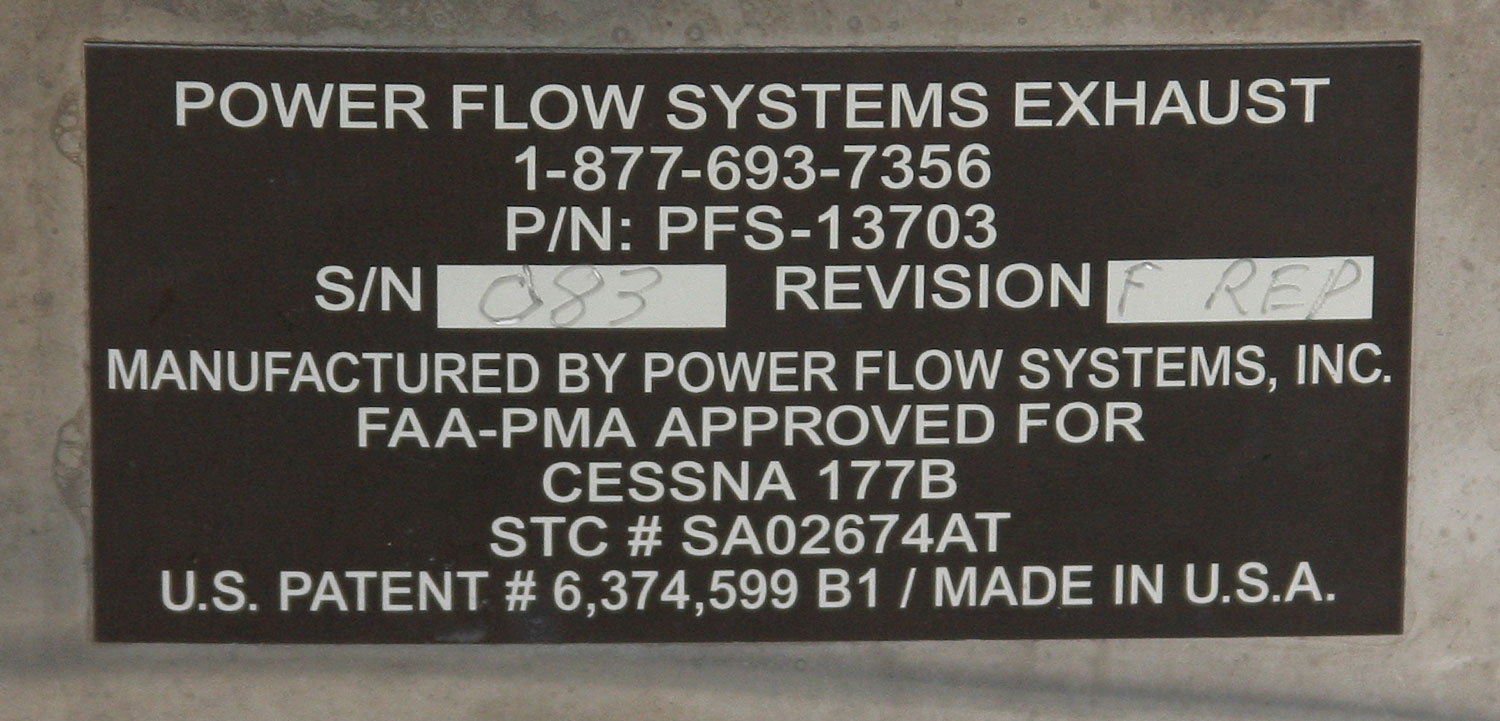

Among other Power Flow requirements is cockpit installation of a placard stating, “The Power Flow Systems, Inc. tuned exhaust system installed on this aircraft may cause the aircraft to burn more fuel at certain power settings. It is the pilot’s responsibility to determine what, if any, change in fuel flow exists and to plan accordingly.”

Discrepancies

Upon completion of an annual inspection, the aircraft owner may be presented with a list of discrepancies that render the aircraft unairworthy. It would be accompanied by a logbook entry stating: “I certify that this aircraft has been inspected in accordance with an annual inspection, and a list of discrepancies and unairworthy items dated _________ have been provided for the aircraft owner.” The listed items could be something rather simple to correct such as a worn tire or frayed seat belt. It could be something more serious, like a cracked wing spar.

Discuss the necessary repairs with the inspector. In the case of a tire or seat belt making the aircraft unairworthy, those items can be replaced by the aircraft owner/pilot as preventive maintenance and the aircraft returned to service with a logbook entry which now deems the aircraft status as airworthy.

How is a determination of an unairworthy condition made? The inspector must refer to data presented in publications such as the manufacturer’s maintenance manual, airworthiness directives, TCDS, instructions for continued airworthiness and Advisory Circular AC 43.13. Conditions of all sorts may be annotated such as allowable dimensional limits, leakage, mechanical travel limits and other conditions that make an item unairworthy.

Should there be no information on an allowable limit—such as a fuel leak or maybe a crack in an elevator skin—the inspector must determine whether an item is in a condition for safe operation or needs corrective action, and what that action might be: can the item be repaired or must it be replaced?

Once the discrepancy has been addressed and a logbook entry made by an authorized persona that the discrepancy has been resolved, the aircraft is once again airworthy.

Owner Participation?

Given the excessive cost of aircraft maintenance and the difficulty that can be encountered when trying to obtain parts, as the owner of an aircraft you should become very familiar with the annual inspection process. Be mindful of just how owner participation in the maintenance of your aircraft can not only reduce your costs but also increase the usefulness of your aircraft.

You’ll certainly learn more about your aircraft by participating with the annual inspection than if you stayed home and just signed the check later. You may even be able to save some money down the road by learning how to perform various tasks you might otherwise need to pay a mechanic to do for you.

Not all maintenance shops allow owner participation on annuals, or do them cheerfully. If your preferred facility doesn’t, you have a choice. The greatest danger is to your wallet, as some shops will go out of their way to find things wrong with a plane sitting in their hangar for a few days. By participating, and being on-site, you have greater control over the process.

While not part of the annual, owners/operators may want to accomplish other required inspections while the aircraft is “down” and opened up. Depending on the shop’s equipment and certifications, you may want to combine an annual with various other inspections, including:

While not part of the annual, owners/operators may want to accomplish other required inspections while the aircraft is “down” and opened up. Depending on the shop’s equipment and certifications, you may want to combine an annual with various other inspections, including:

- Altimeter system and altitude reporting equipment tests and inspections IAW FAR 91.411;

- Transponder tests and inspections IAW FAR 91.413; and

- ELT test and inspection IAW FAR 91.207(d).

Also, while the airplane is opened up may be a good time to install some upgrade or another. But the inspections listed above and installation of new equipment isn’t part of the annual itself. Work that is not essential to the inspection likely will need to be negotiated with the shop.