Not a flight goes by when I don’t think about the potential for a landing-gear problem. It’s not that I’m a pessimist and think something is bound to happen—I don’t—but the moment you fly a complex aircraft, you’ve multiplied the number of things that can go wrong. I bristle when someone trots out the old “there are those who have and those who will” maxim about gear-up landings. It’s just not that simple.

288

Most days you don’t think twice about landing-gear issues, or any others, for that matter, and you take off and land without a problem. Most days. This is the tale of one day during which my attention became very focused on my airplane’s landing gear, and what can go wrong.

Flashback

I’m in the cockpit alone with my thoughts while the folks with mechanical powers are attempting to make a temporary repair on my landing gear that will enable me to move the plane from the wrong side of the hold-short line of the only operational runway at my home airport. I just spoke with a tower controller, a familiar and friendly voice, who advised me the Miami FSDO now knows about my aircraft, that the FAA in Washington, D.C., was notified too, and I should expect an agency representative shortly. The conversation with the tower served to remind me of two lessons learned in my private pilot training: tower controllers are nice people—emphasis on the “people” part—and there may come a day when you arrive at your destination airport and it will be closed due to an accident on the runway. I always saw myself arriving at the closed airport prepared, since I’d paid attention to this lesson—I never believed I would be the one in the left seat of the injured airplane. A new perspective indeed.

At times like these, you go through all of the actions that led up to this point—at least I do. I want to figure it out, solve it, find the failure point. There were no obvious signs of a mechanical problem during pre-flight, but I did not crawl on the ground and test the tension of every bolt in the landing gear, either. Did I look at the gear for obvious problems? Of course. Could I have done more? I think you can always do more, look harder and be more thorough. Still, there comes a time when you know the weak points, both personal and mechanical, and make a judgment call, answering the “Are we safe to fly?” question with “Yes.” Thinking back through the flight itself, everything was normal when we departed, though there may have been an indication of what was to come.

First Hint?

I had flown the airplane three days earlier, which in retrospect turned out to be a good thing. I haven’t flown as much as in years past because of a new adventure—another advanced degree at a local college—and consequently some of the recreational time I would spend in the airplane has turned into study and school time. I’m glad I didn’t face the coming emergency completely out of practice.

My husband and I were heading out to go soaring at an airport about a half hour away; there was rain in the area, so I didn’t want to box myself in and commit, just yet, to making the flight. We’d take off, take a look, and either come back or head out.

There are three runways at my home airport, but only 15/33 is operational. The airport is on the east coast of south Florida, and most summer days the wind is from the south. This week they were easterly, and today the winds were from 080—almost a direct crosswind. With a line of trees to the left of the runway, I expected it to be a little “uneven” as we took off. As I got close to rotation, the aircraft swerved—not much, but it was noticeable. I attributed it to the crosswind, gustiness and a general lack of finesse on my part. I even mentioned it out loud—“Wow, not sure what I was doing there, but that wasn’t the straightest takeoff.” In retrospect, that may have been my early warning.

Airborne and climbing, I worked to correct back to the runway centerline, confirmed my airspeed, flipped the gear switch at the end of the runway and raised the flaps. For some reason, I did not follow the gear handle to its gear-up position as I had been taught.

On this airplane, a Piper Comanche 250, when the gear is raised, the manual gear-extension handle—a telescoping eight-inch-long lever sticking up through the floor at the base of the nosewheel well—transitions from perpendicular to horizontal. It’s out of your field of view, but with your hand along your calf, you can follow the path of the lever.

Instead, I was busy looking for traffic that had been called out by the tower, and for weather. At pattern altitude, I noticed the green “gear down” light was on, but it didn’t really register at first. A few seconds lapsed before I noticed the lack of ground speed and more importantly, the need to really pay attention to controlling the aircraft in the wind. I looked over the panel again and confirmed what I was seeing: the green “gear down” light glowed while the gear handle was in the “gear-up” position with no amber “gear-up” indicator. Having the gear down is not a problem in my book. Not having the gear come down is, but that’s a story I’ve told before (“Think Outside The Box,” Aviation Safety, May 2011). I turned the airplane back toward the airport and advised the tower I was coming back to land.

The Event

I was doing my best to concentrate and push aside the thoughts of “this may not end well.” Those thoughts were there, but they had to sit and wait a few minutes. I approached at a reasonable angle and a reasonable speed, not too steep and not too slow—I didn’t want to put too much downward pressure on the gear, but I was reluctant to use two notches of flaps for a soft-field landing since the crosswind was gusty. The first few hundred feet on the ground were textbook, but as the airplane slowed, it jerked right and headed left—straight for a runway marker sign and two runway lights, which we barely missed as the airplane continued its screeching turn to the left, then came to rest 180 degrees from the direction we came.

288

The tower controller immediately called to ask if we were okay; I confirmed we were, but wanted to check on the airplane before continuing. I shut down the engine and my husband got out to look. The left main gear was at a right angle from where it should have been. I notified the tower I would not be moving the airplane and for the next half hour there was a flurry of activity during the transition from an active GA airport to a closed airport with no available maintenance personnel on the field.

Emergency Takeoff?

Waiting in the left seat, going over the events of the day that led up to this, my thoughts turned inward. How did I contribute to it? For one thing, I didn’t approach today’s flight with much time to spare. The ticking clock is my biggest struggle—I lead a busy life and there is always something that needs to be done or somewhere I need to be. I know very few people who fly who aren’t busy. Being busy isn’t an excuse, but it’s a reality. It’s difficult to be right here, right now, only thinking of “this” and “now.” I’ve coped with it, and come to believe it’s a managed risk.

I had already loosely planned my day, but as the morning hours ticked away, it got more and more apparent that we needed to go flying so I could get back to my homework. A reminder that “there’s no such thing as an emergency takeoff” would have helped, but instead, I kept the target of flying in sight. Flying is enjoyable because I can plan and think ahead—but let me never exchange pre-flight inspection time for “saving time.”

If I had not flown a few days before this event, I would have been anxious about being out of practice. But because I had flown recently, I may not have paid as close attention to details on the airplane. I may have been “looking,” but not “seeing.”

During the flight, why hadn’t I followed the gear lever with my hand? Weather—I was looking around at the weather. There were showers in the vicinity that hadn’t shown up on radar but were now clearly going to impact the airport shortly. We would have to fly around them to go west, away from the traffic corridor along Florida’s east coast, and proceed south. I was busy assessing, not busy flying. That’s why it took a couple of seconds for the gear light to not make sense—I looked, I saw something was out of place, but I didn’t really recognize what it was.

Happy Ending

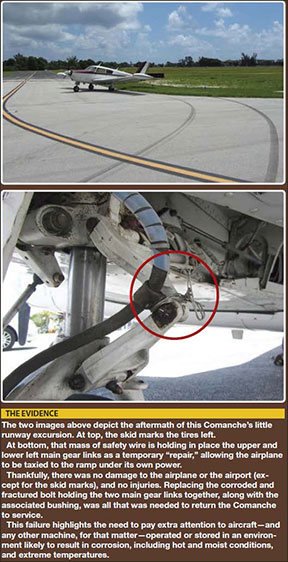

After two and a half hours on the runway, my airplane taxied to the ramp under its own power, with me at the controls. That felt good. The landing gear wasn’t fixed, only wired in position to get me to the ramp. It remained to be seen what damage was done.

I didn’t want to write this and come to the conclusion that I’d done everything right, that the aircraft is in impeccable shape and, as they say, stuff happens. Yes, a mission-critical bolt sheared for an as yet undetermined reason. Bad part? Bad maintenance? A little of both?

I have the required maintenance performed and get issues taken care of when I spot them. Aside from that, I need to look at the environment I operate in, and I need to do more to keep flying trouble-free. I’m just a regular girl, with a regular job, and somehow I manage to own an airplane. It’s not kept in a hangar—the cost of hangaring is out of reach. My tradeoff, then, is to store it on the ramp. Did I want to keep my airplane accessible or spend all of my potential flying time driving to some remote airport with affordable hangars?

Having my airplane close was the obvious answer. But the reality is that South Florida is a harsh environment, which takes a toll on everything, including airplanes. It’s commonly accepted that flying an airplane is good for it and leaving it sitting is not, but leaving it in the Florida coastal region has a unique set of challenges.

I was lucky—no one was hurt, and the airplane wasn’t damaged. A cracked bolt and new bushing were the only parts replaced. The opportunity to learn had presented itself again. The weakest link wasn’t the sheared bolt. It was me.